RAETTS Products

Experts for air suspension and magnetic levitation technologies.

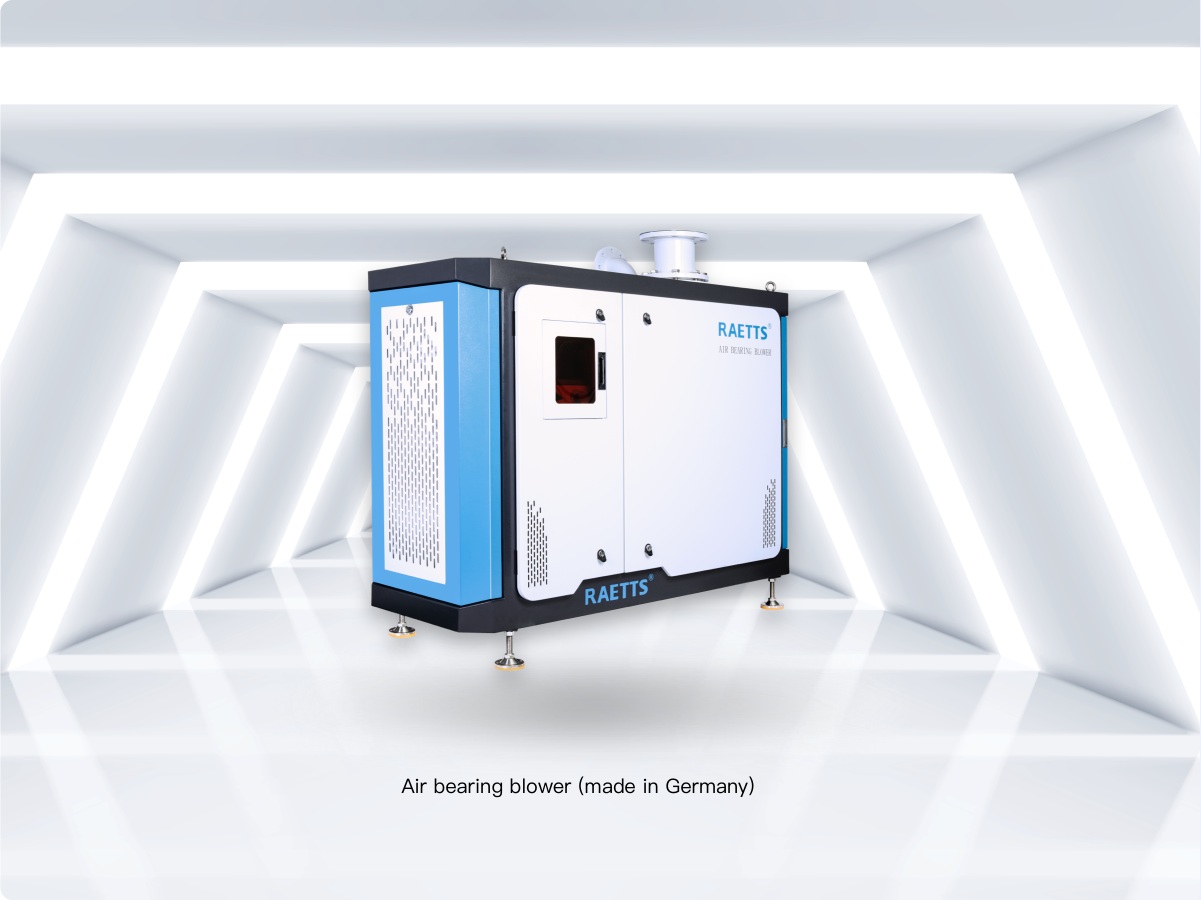

RAETTS air bearing blower adopts aviation turbine technology, since there is no physical friction between impeller and shaft, so it is no need to do maintenance for a long period, and the service life can reach semi-permanent. The core components are air suspension bearings, permanent magnet ultra-high-speed motors, and high-precision aviation-grade impellers,therefore RAETTS air bearing blower/compressor has the characteristic of high efficiency, low noise, and low energy consumption. They are the best choice for transforming Roots blowers.

RAETTS air bearing turbo blower is a brand-new concept blower, which integrates the main core technologies such as “air suspension bearing”, “permanent magnet ultra-high-speed motor”, “high-precision aviation-grade impeller”, and creates a new era of ultra-high efficiency ,low noise and low energy consumption. Since there is no physical friction between impeller and shaft, so it is no need to do maintenance for a long period, and the service life can reach semi-permanent. It has been certified as an “Energy Efficiency Star” equipment product by the state and won many honors.

WORK PRINCIPLE

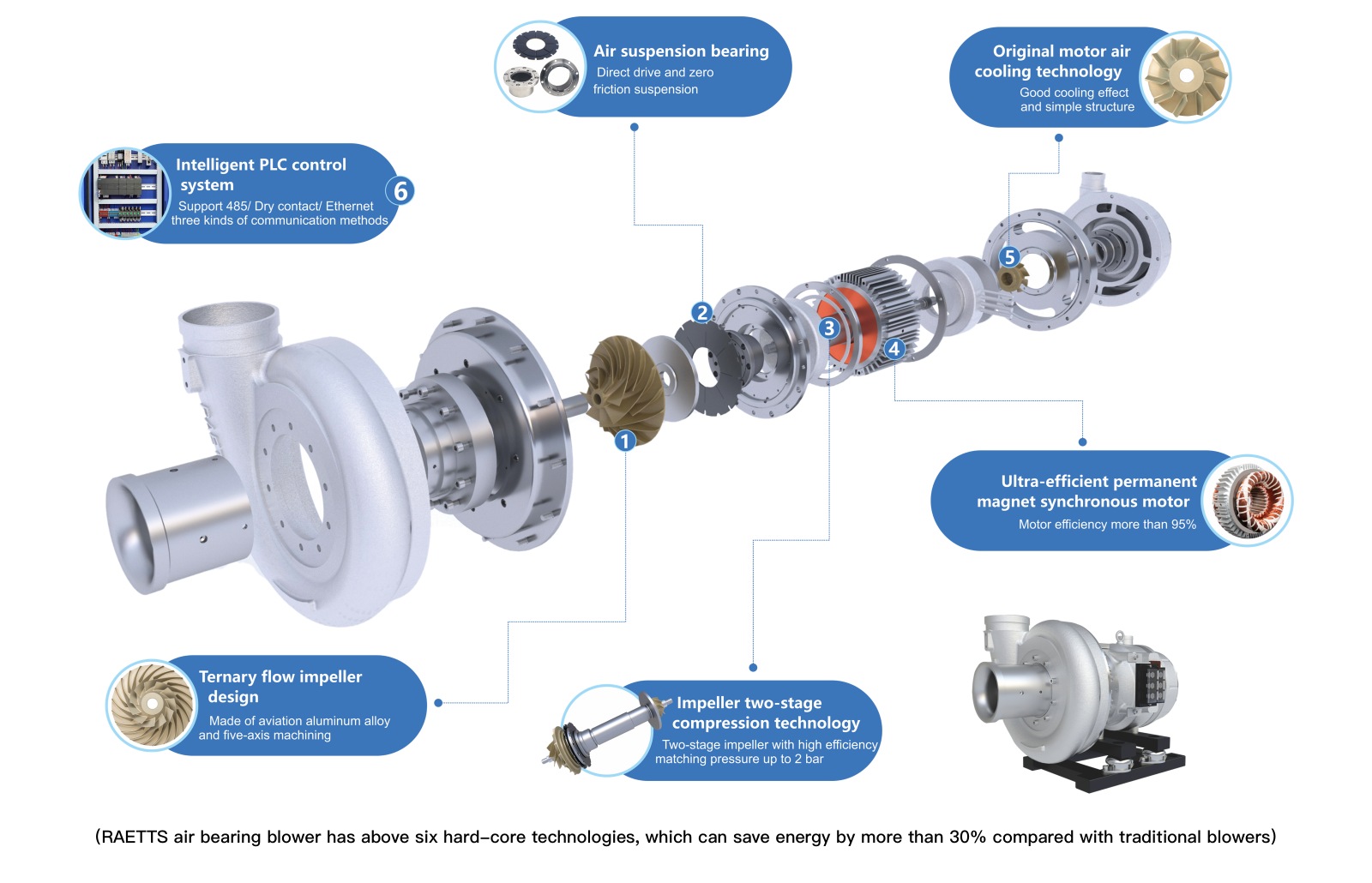

RAETTS air suspension bearing blower is a kind of centrifugal blower in which the air will generate a dynamic pressure effect between the rotor and the foil bearing surface under the high-speed rotation of the blower rotor, forming a high-pressure air film to float the rotor. Since the air bearing blower is adopting oil-free passive air suspension bearing, there is no oil lubrication required.The structure is simple and precise. RAETTS air bearing turbo blower is a product extended from the technology of the aircraft turbine engine. Its main core technologies are air suspension bearing technology, high-speed permanent magnet synchronous motor and its control technology. The air suspension bearing uses air as the working medium, the elastic flat foil (top foil) as the supporting surface, and the elastic wave foil (wave foil) as the supporting member.

01

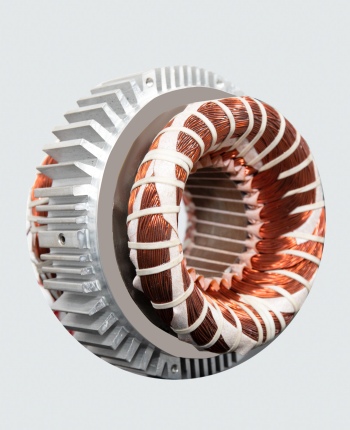

Ultra-efficient permanent magnet high-speed motor technology

RAETTS air suspension bearing blower is a kind of centrifugal blower in which the air will generate a dynamic pressure effect between the rotor and the foil bearing surface under the high-speed rotation of the blower rotor, forming a high-pressure air film to float the rotor. Since the air bearing blower is adopting oil-free passive air suspension bearing, there is no oil lubrication required.The structure is simple and precise.

RAETTS air bearing turbo blower is a product extended from the technology of the aircraft turbine engine. Its main core technologies are air suspension bearing technology, high-speed permanent magnet synchronous motor and its control technology. The air suspension bearing uses air as the working medium, the elastic flat foil (top foil) as the supporting surface, and the elastic wave foil (wave foil) as the supporting member.

02

Air suspension bearing technology

100% oil-free suspension bearing, no mechanical friction, and the service life can reach semi-permanent. No mechanical noise, no mechanical vibration, just conveying air. It has been widely used in industrial machinery since 2000. It has a simple structure.Compared with oil-lubricated bearings, it can run stably at high temperatures. It has better suspension capabilities in permanent magnet high-speed motors, and does not require complex sensor systems.

03

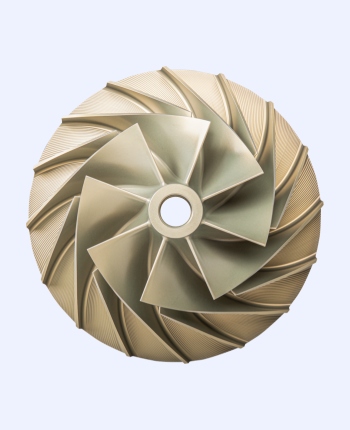

Aviation aluminum alloy impeller

RAETTS air bearing turbo blower adopts high-strength aviation aluminum alloy impeller to facilitate high-speed operation in air suspension bearings. The design precision can reach 0.001mm to ensure operating efficiency. The impeller surface adopts hard anode and other treatment methods,which can maintain high-efficiency operation even in harsh environments.

04

The world's original motor cooling technology

The motor of RAETTS air bearing blower adopts double-stages cooling structure system,and the cooling effect is more stable.The first stage is air-cooled inside the motor, and second stage is effectively cooled for air bearing assembly of the motor.This double-stages cooling system structure is so powerful that it does not require additional cooling equipment (such as externally connected forced cooling fans, etc.) in our motors.

05

Two-stage compression technology

when the pressure is below 1.2kg,our air bearing blower adopts the single-stage air compression technology;when the pressure is between 1.2-4kg,RAETTS air bearing blower adopts the double-stages air suspension bearing compression technology, which has extremely high efficiency.

RAETTS blower advantages:

Thanks to the world’s advanced energy-saving blower technology, RAETTS air bearing blower can save energy by more than 30% compared with traditional blowers,and more than 5% compared with the same specific blowers.

Applications case sharing

Project Name: Phase I project of Mabaolong Sewage Treatment Plant in Yilong Town, Shiping County, Yunnan Province,China.

Before the renovation of the project:the traditional centrifugal blower has high energy consumption, high noise and high maintenance cost.

After the renovation of the project:10sets RAETTS air foil bearing blower (2sets EXPL 75-06 55kW; 2sets EXPL 100-06 75kW; 6sets EXPL 50-06 37kW)

The main parameters:

EXPL 75-06 55kW flow rate 51m³/min, pressure 60kPa

EXPL 100-06 75kW flow rate 34m³/min, pressure 60kPa

EXPL 50-06 37kW flow rate 70m³/min, pressure 60kPa

Energy saving effect:about 30%

Annual electricity saving:10sets RAETTS air bearing blower can save more than 200,000$ in electricity the whole year.

Payback cycle:estimated one year

Project Introduction

This sewage treatment plant in Shiping County, Honghe Prefecture, Yunnan Province is located in Mabaolong, Yilong Town, Shiping County, covering an area of 5.54acres. It has built two biochemical pools with a treatment scale of 10,000 m3/d and one storage tank with a capacity of 8000 m³, and adopts CASS+ advanced treatment Process, factory water quality implementation standard is “Urban Sewage Treatment Plant Pollutant Discharge Standard” (GB18918-2002) Class A standard. The scope of service is the urban area of Shiping County, and the service population is 62,500 people recently. The project started construction in October 2009 with a capacity of 10,000 m3/d. It was completed on December 31, 2010 and tested for water supply. It was officially put into operation on September 22, 2011. In May 2013, it passed the environmental protection inspection. In October 2017, the construction of the first phase relocation project of 10,000 m3/d was completed and put into operation, and the processing scale is now 20,000 m3/d.

Before the upgrade and renovation, the Shiping County sewage plant used traditional centrifugal blower for blowing and aeration, which consumes a lot of energy, makes a lot of noise, and requires high maintenance costs. After researching and understanding the status and needs of the project, RAETTS professional technicians selected 10 sets of conventional pressure air suspension bearing blower for the plant to meet the needs of various working conditions and achieve the purpose of good energy saving, noise reduction and low-cost maintenance.

RAETTS Intelligent Equipment(Guangdong) Co., Ltd.

RAETTS Intelligent Equipment (Guangdong) Co., Ltd.

Customer Reviews

RAETTS air bearing blower adopts international advanced air suspension technology. The whole machine is small in size, light in weight, free of oil pollution, and the noise is about 80 dB, which is much lower than the original centrifugal blower. Maintenance cost is very lower and no need to change the blower for operation frequently.Energy saving efficiency is very significant.

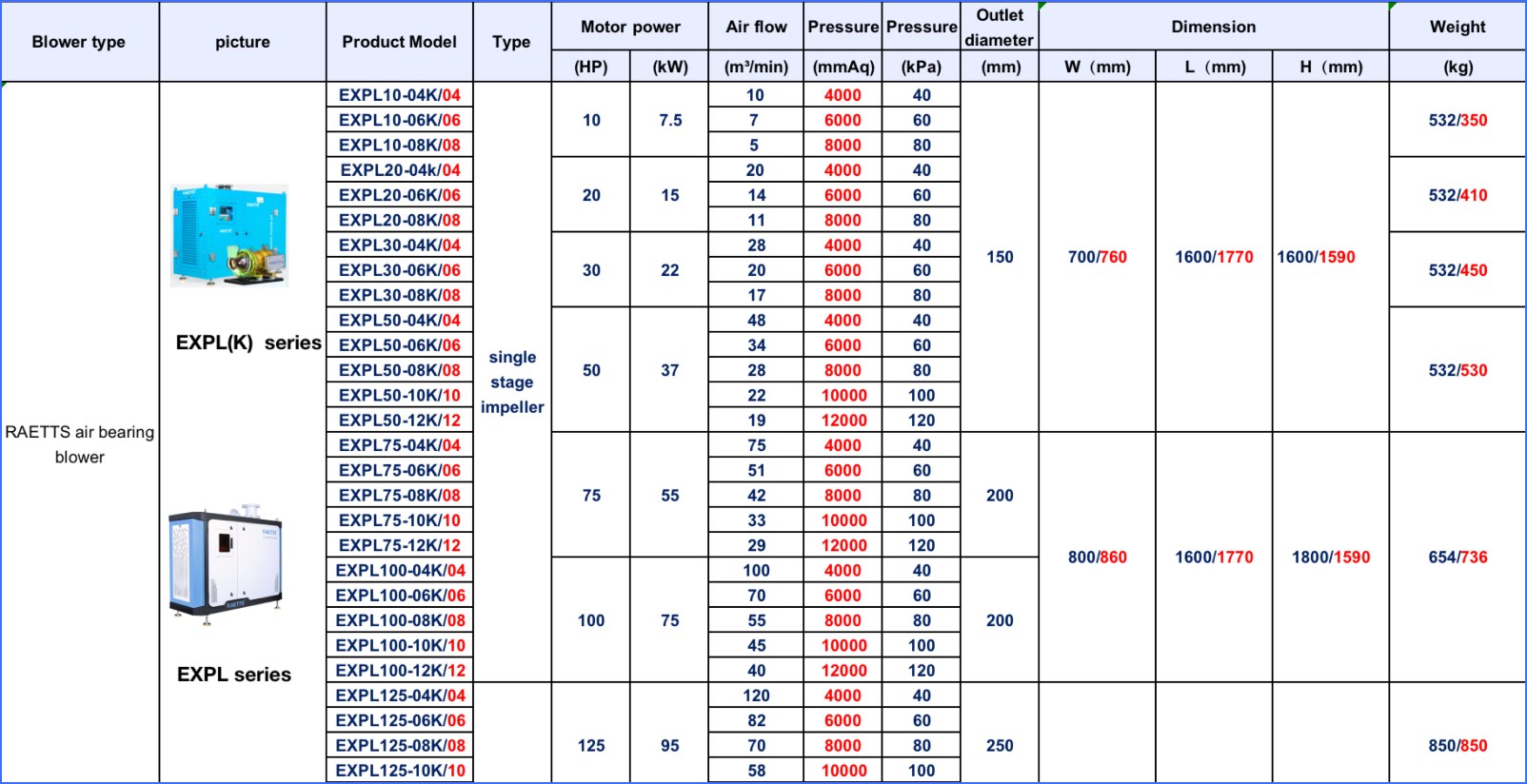

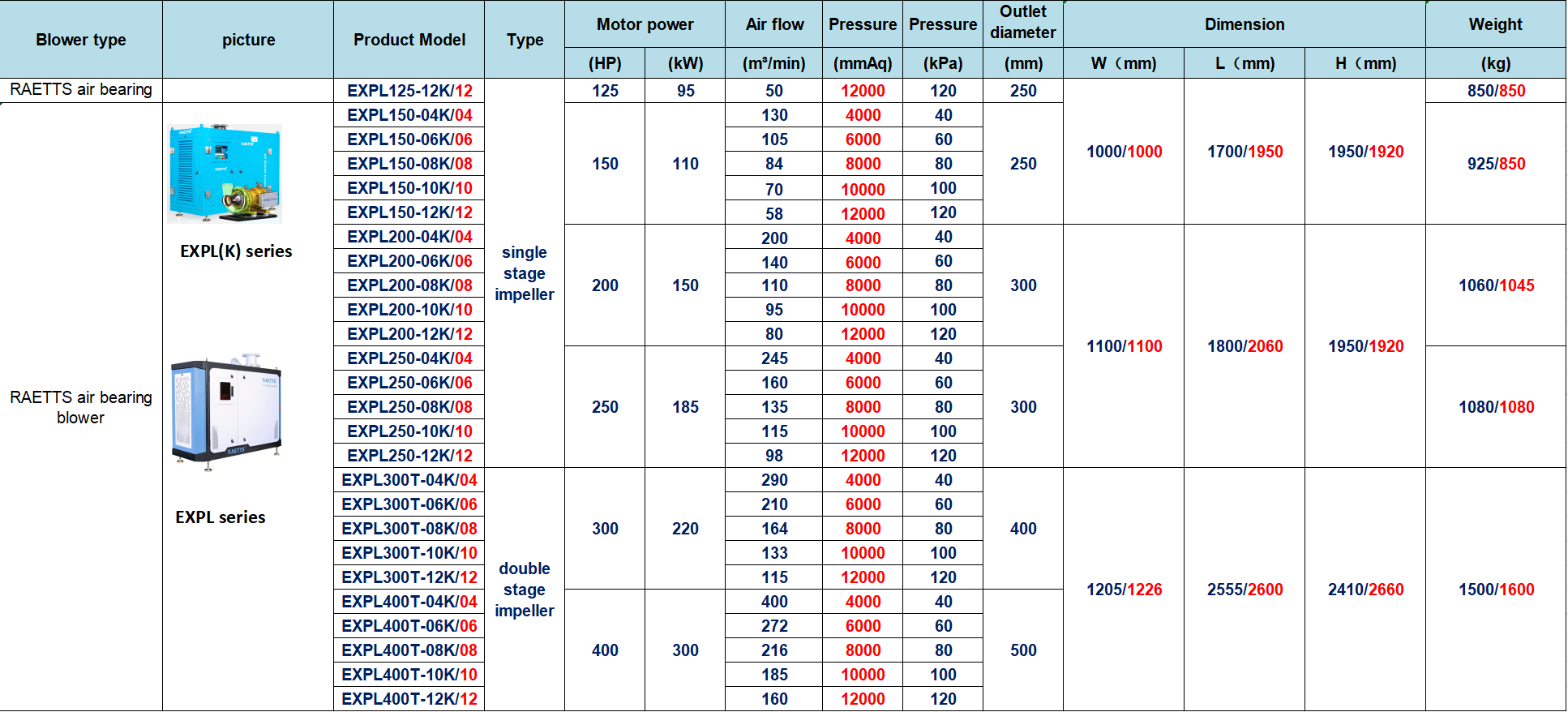

Selection parameters table

RAETTS provides high efficiency and energy-saving system solutions for our global customers,contributing to achieve the goal of carbon peaking and carbon neutrality.

For more information,feel free to click here to submit your request,our professional team will contact you soon

RAETTS High-Tech Park No.3,Juyuan Second Road.Dongguan City,Guangdong Province, China

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)

BelPragma LLC

Address: Republic of Belarus, Minsk, st. Amuratorskaya, 4, office 214

ENCOTEC Co.,Ltd. Add: 71/296 Soi.Ramkhamhaeng 164,Ramkhamhaeng Rd.,Minburi,Bangkok 10510,Thailand

T&T Pacific Sdn Bhd Add:No.31, Jalan PJU 3/49,Sunway Damansara,47810 Petaling Jaya,Selangor Darul Ehsan

Add:21 Center Drive, Hillsdale, NJ 07642

ASAP Servicios Técnicos Add:Calle Zinc 1, Nave A,28770 Colmenar Viejo, Madrid (Spain)

Adresse : 80 Rue Isabelle Eberhardt, 34000 Montpellier.

Telephone: 0033(0)652678173

PRODUCTS

RAETTS GROUP

Asia HQ:

Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)

CONTACT US

0769-81190028

sales15@raetts.com