Revolutionizing Beverage Production: Heat Pump Application for Temperature Control in Production Areas

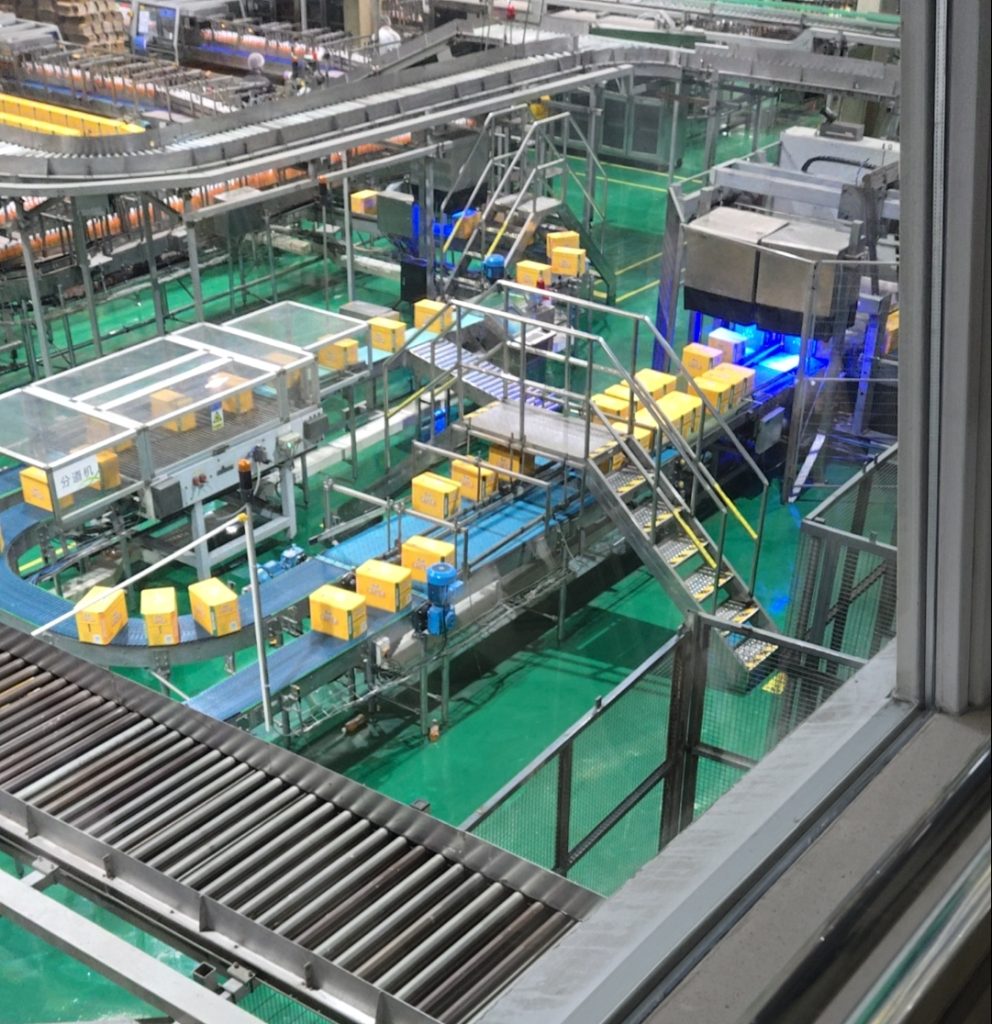

In beverage manufacturing, efficient temperature control is critical to maintaining the quality of products and optimizing energy consumption. Recently, a low-temperature magnetic levitation heat pump system was implemented in a beverage production facility to improve cooling efficiency and reduce reliance on traditional steam heating systems. This innovative solution provides a sustainable alternative to the conventional method of steam heating while also enhancing operational efficiency.

In this article, we will explore the application of heat pumps for cooling production areas and heating water in beverage factories. We will also review the key data and comparisons to highlight the cost savings, energy efficiency, and operational benefits achieved through this upgrade.

Client Requirements and Challenges

The client required cooling for a production area of 4,205 square meters to maintain the optimal temperature for beverage production. The area was to be served by air supply units, ensuring consistent cooling and temperature control across the workspace. Additionally, the production lines required hot water at temperatures between 40-50°C, traditionally achieved by steam heating.

Key Parameters:

- Cooling Requirements:

- Hot Water Demand:

- Energy Consumption and Heating:

Existing System’s Limitations

The traditional steam heating system used for hot water generation presented several limitations:

- High energy consumption and operational costs associated with steam boilers.

- The need for large quantities of steam energy to heat water for sugar dissolution and extraction processes.

- Inefficiency in energy use, leading to higher fuel costs and environmental impact.

Low-Temperature Magnetic Levitation Heat Pump Solution

To address these challenges and improve operational efficiency, the beverage plant transitioned to using a low-temperature magnetic levitation heat pump system. After carefully evaluating the site’s needs and product specifications, the solution involved a single RAETTS ultra-low-temperature magnetic levitation heat pump unit. This system was designed to meet both the cooling and heating demands of the production facility.

Key Features of the Heat Pump System:

- Cooling and Heating Capacity:

- System Components: The solution includes a water pump, plate heat exchanger, and insulated water tank, working together to maintain optimal energy use and efficient temperature control.

Performance and Energy Savings: A Comparison

Old System (Steam Heating + Cooling with Fans)

- Annual Hot Water Consumption: 63,000 tons (heating from 27°C to 55°C)

- Additional Hot Water: 46,980 tons (heating from 27°C to 60°C)

- Total Annual Hot Water Demand: 109,980 tons

- Required Heating Capacity: 873 kW to heat the RO water from 25°C to 50°C.

New Heat Pump System (RAETTS Ultra-Low Temperature Magnetic Levitation Heat Pump)

- Heating Capacity: 879 kW, which is more than sufficient to meet the hot water demand across all production lines.

- Cooling Capacity: 721 kW, designed to efficiently regulate the temperature in the production area.

- Power Consumption: The heat pump system’s energy usage is 176 kW, a significant reduction compared to the energy consumption of the previous steam heating system.

Energy Savings:

- Power Consumption Reduction: The RAETTS heat pump system reduces energy consumption by a significant margin compared to steam-based systems. With a power consumption of only 176 kW, the heat pump ensures high energy efficiency and lowers operating costs.

Benefits of the Magnetic Levitation Heat Pump System

- Energy Efficiency: By transitioning from steam boilers to the RAETTS heat pump, the factory has significantly reduced energy consumption. The low-temperature magnetic levitation technology minimizes energy losses and ensures that both cooling and heating are efficiently managed with lower power inputs.

- Lower Operational Costs: The system’s energy-efficient operation results in lower overall operational costs, with substantial savings on fuel, electricity, and maintenance expenses.

- Environmental Impact: The new heat pump system is oil-free and operates without the need for lubricants or steam, making it a much more sustainable solution than traditional steam heating systems. This reduction in emissions aligns with the facility’s environmental goals.

- Noise Reduction: The RAETTS heat pump operates quietly—a major improvement over the noise levels generated by the previous system’s steam compressors. This creates a more comfortable working environment for staff and helps meet noise compliance standards.

- Reliability and Longevity: Designed to last for over 20 years, the maglev heat pump system offers long-term reliability with minimal maintenance needs, further reducing plant downtime and associated costs.

Conclusion: The Future of Energy-Efficient Beverage Production

The RAETTS ultra-low-temperature magnetic levitation heat pump system represents a major step forward in energy-efficient cooling and heating for beverage production plants. By replacing traditional steam-based systems with cutting-edge technology, the factory has achieved remarkable reductions in energy consumption and operational costs, while enhancing the overall sustainability of its operations.

This project demonstrates the significant advantages of low-temperature heat pumps in beverage manufacturing, not only as a way to reduce reliance on steam but also to optimize energy use, lower operational costs, and improve environmental outcomes. As beverage manufacturers continue to seek ways to increase efficiency, the magnetic levitation heat pump system provides an ideal solution for the future of sustainable production.

By integrating the RAETTS ultra-low-temperature magnetic levitation heat pump, the beverage production facility has not only enhanced its operational efficiency but also set a new standard in energy-efficient industrial systems. As the industry evolves, embracing these technologies will be crucial for companies looking to meet sustainability goals while maintaining high product quality and performance.

If you are considering upgrading your facility with a more energy-efficient aeration and heating system, contact us today to learn how RAETTS heat pumps can optimize your production line and improve overall performance.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424