Air Suspension Blower Retrofit for BYD Fudi Battery Plant: 31% Energy Savings Achieved in 1 Year

1. Introduction: The Urgency of Energy Efficiency in Industrial Applications

In today’s era of carbon neutrality and industrial sustainability, leading manufacturers are actively pursuing innovative solutions to improve energy efficiency and reduce operational costs. RAETTS, as a pioneer in maglev blower technology, recently completed a major retrofit project for BYD Fudi Battery, a core division under BYD Group and a leading global manufacturer of EV power batteries and energy storage systems. This project not only showcases the potential of maglev technology in industrial upgrades but also sets a benchmark for energy-efficient air systems in the battery sector.

2. Project Background: From Traditional Roots to Smart Efficiency

Before the retrofit, the BYD Fudi factory relied on a traditional Roots blower system consisting of one 66 kW unit to support its air supply for wastewater treatment in the battery manufacturing process. However, the system had several shortcomings:

-

High energy consumption

-

Frequent maintenance

-

Noise and vibration

-

Lack of intelligent control

To address these challenges, RAETTS designed a tailored maglev blower upgrade plan, replacing the original system with three 15 kW RAETTS maglev blowers, totaling just 45 kW — a 31% reduction in installed capacity.

3. Technical Highlights: What Makes RAETTS Maglev Blowers Different

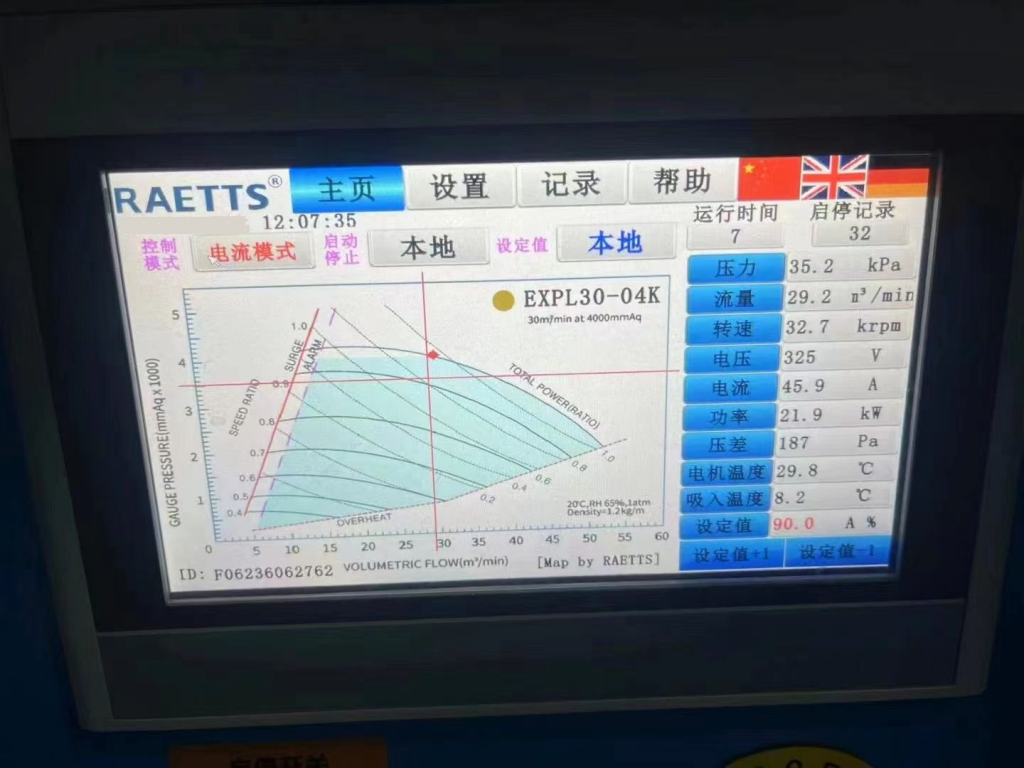

The RAETTS maglev blowers applied in this project offer several cutting-edge advantages:

-

Oil-free Magnetic Bearings: Ensuring zero mechanical contact, reducing wear and extending lifespan.

-

Smart VFD Control: Fully adjustable output for varying load demands, ensuring optimal operation at all times.

-

Compact Design with High Efficiency: Higher air volume per kW and quieter operation compared to traditional blowers.

-

Real-Time Monitoring System: Enables remote control, alerts, and performance tracking for predictive maintenance.

4. Measurable Results: From Cost to Carbon Savings

In just one year of operation, the retrofit yielded outstanding results:

| Metric | Before Retrofit (Roots Blower) | After Retrofit (Maglev Blower) |

|---|---|---|

| Installed Power | 66 kW | 45 kW |

| Annual Power Consumption | ~580,000 kWh | ~400,000 kWh |

| Annual Power Savings | — | 180,000 kWh |

| Electricity Cost Savings | — | RMB ¥135,000 / USD $18,500 |

| Payback Period | — | < 1 year |

| Maintenance Cost | High | Near-zero |

| Noise | 90–95 dB | <75 dB |

This case clearly demonstrates how maglev blower retrofits can drastically reduce operational costs and carbon emissions.

5. Why the Battery Industry Needs Maglev Technology

Battery production, particularly in wastewater treatment and air supply systems, requires stable, oil-free, and energy-efficient air delivery. RAETTS’ maglev blowers fulfill these needs while offering:

-

Clean, non-contaminated air

-

Stable pressure and flow

-

Energy adaptability during off-peak hours

-

Longer lifespan (20+ years)

No wonder more and more battery manufacturers like BYD Fudi are upgrading to RAETTS’ high-efficiency systems.

6. RAETTS: Your Partner in Sustainable Upgrades

This successful case at BYD Fudi Battery highlights not only RAETTS’ technical excellence but also its strong ability to serve top-tier brands with custom solutions. With our proven track record in automotive, water treatment, food and beverage, and semiconductor industries, we are ready to help more global clients reduce their carbon footprint and operational costs.

7. Contact Us

Looking to improve energy efficiency and reduce costs at your plant?

📩 Contact us today for a custom ROI analysis and learn how RAETTS maglev blowers can transform your facility.