From Pond to Power: How RAETTS Explorer High-Speed Air Blower Boosted Aquaculture

Background

Aquaculture is one of the fastest-growing food production sectors in the world, and China — especially Guangdong Province — is at the heart of this industry. In modern fish farming, a reliable and efficient aeration system is essential to ensure optimal water quality, maintain healthy oxygen levels, and support sustainable operations.

In early 2025, a fish farm owner in Guangdong approached RAETTS with a problem. His existing aeration equipment was old, power-hungry, and unstable during peak oxygen demand. The limited space in his facility made it difficult to install larger or more complex systems, and rising energy costs were putting additional pressure on profitability.

Challenges Before the Upgrade

During the initial site inspection, the RAETTS engineering team identified three major issues:

-

High Energy Costs

The previous blower system consumed significantly more power while delivering lower efficiency, leading to higher electricity bills. -

Unstable Oxygen Supply

During hot weather or high-density stocking periods, oxygen levels in the ponds would fluctuate, putting fish health at risk. -

Space Constraints

The facility layout left very limited space for new machinery, meaning any new equipment needed to be compact yet powerful.

The RAETTS Solution — Explorer High-Speed Blower

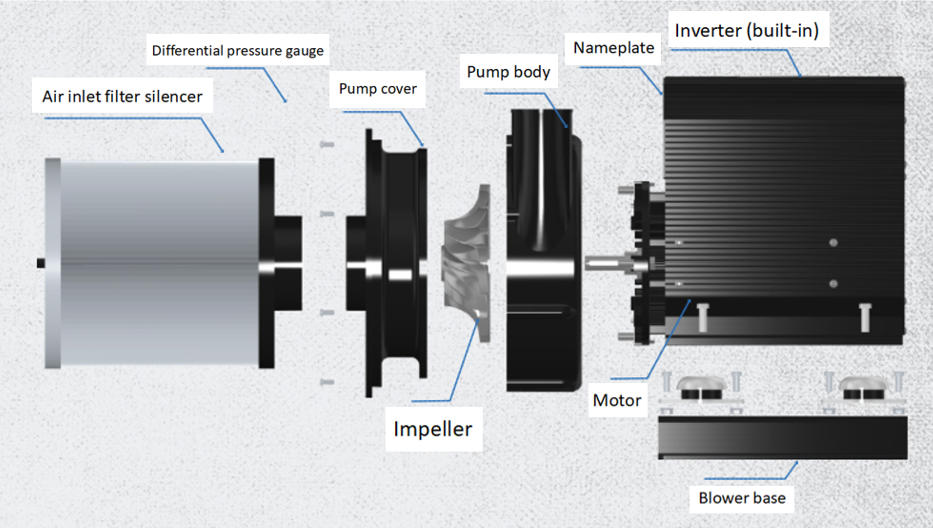

RAETTS proposed installing one RAETTS Explorer high-speed blower with a rated power of 5.5 kW.

The Explorer series is specifically designed for applications like aquaculture, where high efficiency, stability, and compact design are critical. The key features that made it the perfect fit for this project included:

-

87% Energy Efficiency — Optimized performance at low power, significantly reducing electricity costs.

-

Compact & Easy to Install — The small footprint allowed seamless integration into the farm’s limited equipment area.

-

Stable Airflow — Powered by a high-speed Permanent Magnet Synchronous Motor (PMSM) with a built-in frequency conversion system, the blower delivers constant and precise aeration even under changing load conditions.

-

Low Noise (65 dB with silencer) — Quiet operation ensures minimal disturbance to the farm environment and nearby communities.

Installation & Commissioning

The installation process was completed quickly, without the need for heavy lifting equipment or extensive civil modifications.

-

Positioning — The compact design allowed the unit to be positioned next to existing infrastructure.

-

Connection — The blower was connected to the existing aeration pipeline with minimal adjustments.

-

Testing & Fine-Tuning — The RAETTS team monitored oxygen levels and airflow rates to ensure the blower was delivering optimal performance from day one.

Results & Benefits

Within just a few days of operation, the fish farm owner began noticing improvements:

-

~30% Reduction in Energy Costs — Lower operating power meant immediate savings on electricity bills.

-

Consistent Oxygen Levels — Even during high-demand periods, the blower maintained stable oxygen supply, improving fish health and survival rates.

-

Space Optimization — The compact unit freed up valuable floor space, allowing more flexibility for future equipment upgrades.

-

Quieter Operations — Reduced noise levels improved the working environment for farm staff and reduced stress for the fish.

Customer Feedback

The farm owner shared his thoughts after the first month of operation:

“The RAETTS Explorer blower has completely changed the way we manage oxygen in our ponds. Energy bills are lower, the oxygen supply is stable, and installation was fast. I wish we had made the change sooner.”

Why RAETTS Explorer for Aquaculture?

While this project took place in Guangdong, similar challenges exist for aquaculture facilities worldwide — from small-scale operations to large commercial farms. The RAETTS Explorer series offers:

-

Lower operating costs through high efficiency

-

Reliable oxygen supply for healthier aquatic environments

-

Compact size for easy integration

-

Quiet, low-maintenance operation

Conclusion

This Guangdong case study shows how even a single 5.5 kW RAETTS Explorer high-speed blower can deliver a big impact on aquaculture operations — cutting energy costs, stabilizing water quality, and enhancing sustainability.

Whether it’s fish farming, shrimp ponds, or other aquatic environments, RAETTS provides advanced blower technology that’s built for performance and efficiency.

📩 Contact RAETTS today to learn how our Explorer series can power your aquaculture project to success.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424

#Aquaculture #FishFarming #AquacultureTech #Aeration #Oxygenation #WaterQuality #TurboBlower #EnergyEfficiency #LowNoise #CompactDesign #SustainableOperations #RAETTS #ExplorerBlower