Direct drive PMSM with >97% efficiency

No contact, no oil, no friction, almost zero maintenance

Smart VFD control, precisely matching airflow demand and avoiding energy waste

Integrated rotor + aerospace-grade 3D impeller

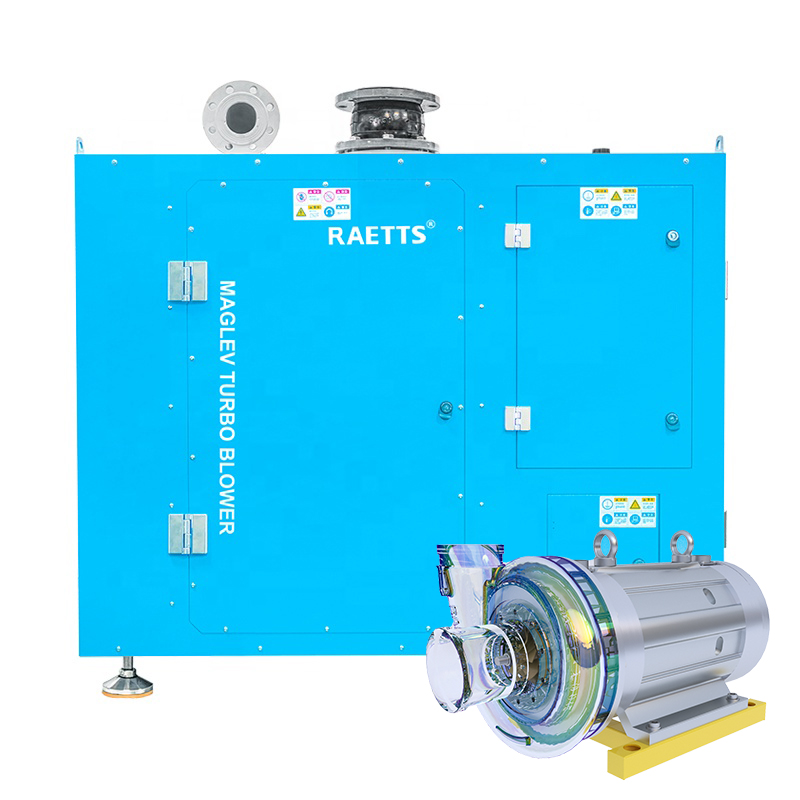

Maglev (magnetic levitation) turbo blowers use high-speed, oil-free motors with magnetic bearings. These state-of-the-art machines eliminate mechanical friction and offer superior control through variable-speed drives.

Maglev (magnetic levitation) technology revolutionizes the blower industry by eliminating mechanical contact between rotating components. Instead of using traditional ball bearings, RAETTS maglev turbo blowers employ active magnetic bearings to suspend the shaft in mid-air, allowing it to spin at ultra-high speeds with zero friction.

This contactless design means:

No lubrication is needed

No mechanical wear occurs

Efficiency is significantly improved

Maintenance is drastically reduced

Maglev technology enables higher speeds, lower energy consumption, and longer service life—making it the ideal solution for modern, energy-efficient, and eco-friendly aeration systems.

Ultra Energy Saving

RAETTS maglev turbo blowers adopt advanced magnetic levitation technology and high-speed permanent magnet synchronous motors, which significantly reduce energy consumption—saving up to 30–50% energy compared to traditional blowers.

Ultra-High Efficiency

With oil-free, contactless bearings and precision aerodynamic design, RAETTS blowers achieve efficiencies over 80%, delivering stable and consistent airflow while minimizing mechanical losses.

Environmental Protection & Low Noise

The oil-free design eliminates the risk of lubricant leakage, making it clean and eco-friendly. At the same time, the magnetic bearing system ensures super-quiet operation, reducing noise to as low as 75 dB(A)—ideal for urban and indoor installations.

Simple Structure, Easy Maintenance

Thanks to the contactless magnetic bearing and integrated motor-compressor system, there are fewer moving parts, reducing mechanical wear and drastically lowering maintenance costs and frequency.

Ultra-Long Life Span

No friction, no lubrication, no mechanical contact—this results in exceptionally long service life, often exceeding 20 years, ensuring long-term reliability and reduced total cost of ownership.

Wastewater Treatment Plants

Maglev blowers are widely used in aeration tanks for biological treatment processes. Their high energy efficiency, low noise, and minimal maintenance make them ideal for 24/7 operation in harsh sewage environments. They help reduce operating costs while ensuring stable dissolved oxygen supply.

Cement and Chemical Plants

In cement and chemical manufacturing, process air must be stable, clean, and reliable. RAETTS maglev blowers deliver oil-free, dry air that improves process safety and product quality, especially in fluidized beds, material transport, and cooling applications.

Textile Industry

Maglev blowers are perfect for dyeing, drying, and finishing equipment, where continuous, high-volume air is needed. They replace inefficient roots blowers and reduce energy consumption by up to 30–50%, helping factories lower their carbon footprint.

Electronics & Semiconductor Industry

Cleanrooms demand ultra-clean, oil-free air for chip manufacturing, coating, and packaging. RAETTS maglev blowers ensure contaminant-free airflow with minimal vibration—critical for sensitive production environments.

Food & Beverage Processing

In applications like fermentation, drying, air conveying, and aerated mixing, RAETTS blowers offer hygienic, oil-free operation. Their low noise and compact footprint make them easy to install in production facilities.

Aquaculture and Fish Farming

Stable oxygen supply is vital for aquatic health and growth. RAETTS blowers provide continuous, energy-efficient aeration for fish ponds and RAS (recirculating aquaculture systems), improving productivity and water quality.

Biogas, Landfill Gas, and Environmental Projects

RAETTS maglev blowers are used to enhance gas collection, maintain optimal pressure levels, and support methane recovery. Their robust design performs well in corrosive and challenging environments, contributing to better environmental control and energy recovery.

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)