In this article, we will reveal why RAETTS Maglev Turbo Blower is suitable for wastewater & general industrial applications

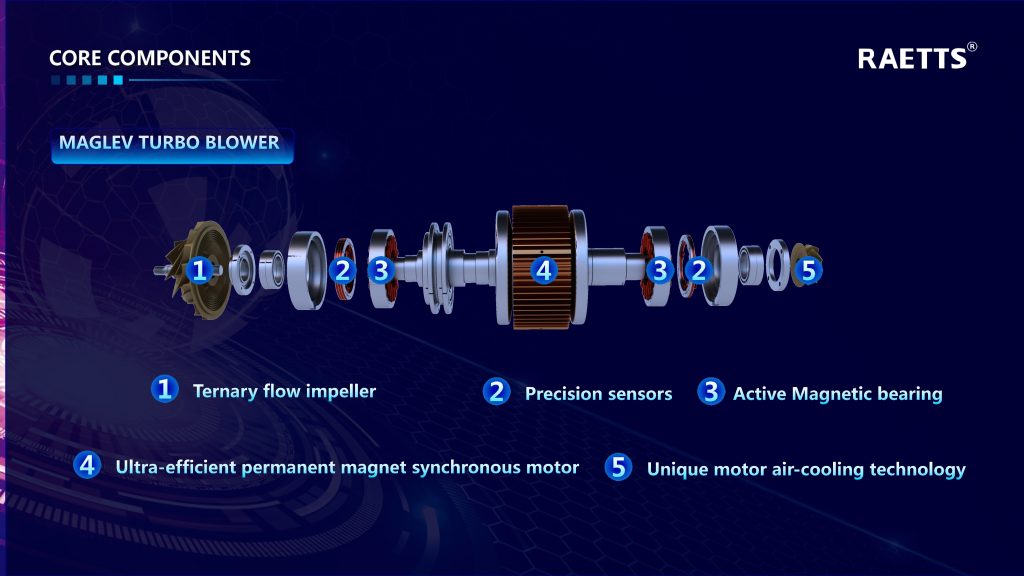

RAETTS Maglev Turbo Blowers have permanent magnet synchronous motors (PMSM). These provide a much higher operational velocity, output, and performance than traditional induction motors.

PMSMs are powered by an alternating current that is run through the stator coils to create a rotating magnetic field, while fixed permanent magnets attached to the rotor create a constant magnetic field. At a synchronous speed, the poles generated by the rotor’s magnets lock onto the magnetic field generated by the stator, causing the rotor to turn in sync with the frequency of the current running through the stator.

This allows PMSMs to operate without any ‘slip’ or ‘lag’ in the rotor, making them inherently more efficient than traditional induction motors. Providing a direct connection to the blower’s impeller, PMSMs ensure no power loss, regardless of the blower’s operating speed or conditions.

RAETTS Maglev turbo blowers use innovation and advanced technology delivering energy savings of up to 40%. These turbo blowers provide increased reliability with low maintenance requirements and are factory prewired and tested in an ergonomically designed sound enclosure for plug-and-play operation.

All RAETTS Maglev Turbo Blowers are fitted with a inverter and Siemens PLC as standard. The inverter adjusts the PMSM motor’s operating speed to meet operational requirements. Allowing operators to tailor the performance to meet oxygen demand, which further increases the levels of efficiency that they can provide.

Over time, equipment maintenance requirements, parts, and spares, as well as downtime and process upsets can impact the total cost of ownership and operational costs. That is why it is crucial to select equipment that meets efficiency requirements and is designed to withstand the process and environmental demands.

RAETTS ’s Maglev Turbo Blower combines an advanced blower management system with a significantly smaller physical footprint than traditional blowers to set a new standard for blower design, performance, and efficiency.

For example, a 37KW RAETTS Maglev Turbo Blowe (model CXPL50-08, rated pressure 80kPa, rated air flow 28m3/min, DN150), the dimensions is L1750*W850*H1640 (mm) and weighs 750kg. It is small and light.

PRODUCTS

RAETTS GROUP

Asia HQ:

Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)

CONTACT US

0769-81190028

sales15@raetts.com