How Does a Turbo Blower Differ From a Traditional Roots Blower?

(A Complete Comparison for Wastewater Treatment Plants)**

In modern wastewater treatment plants, aeration accounts for 40–60% of total power consumption.

This is why the choice of blower technology directly affects operating cost, plant stability, and long-term lifecycle performance.

As more WWTPs move toward energy-efficient upgrades, one question comes up repeatedly:

👉 “What is the difference between a turbo blower and a traditional Roots blower?”

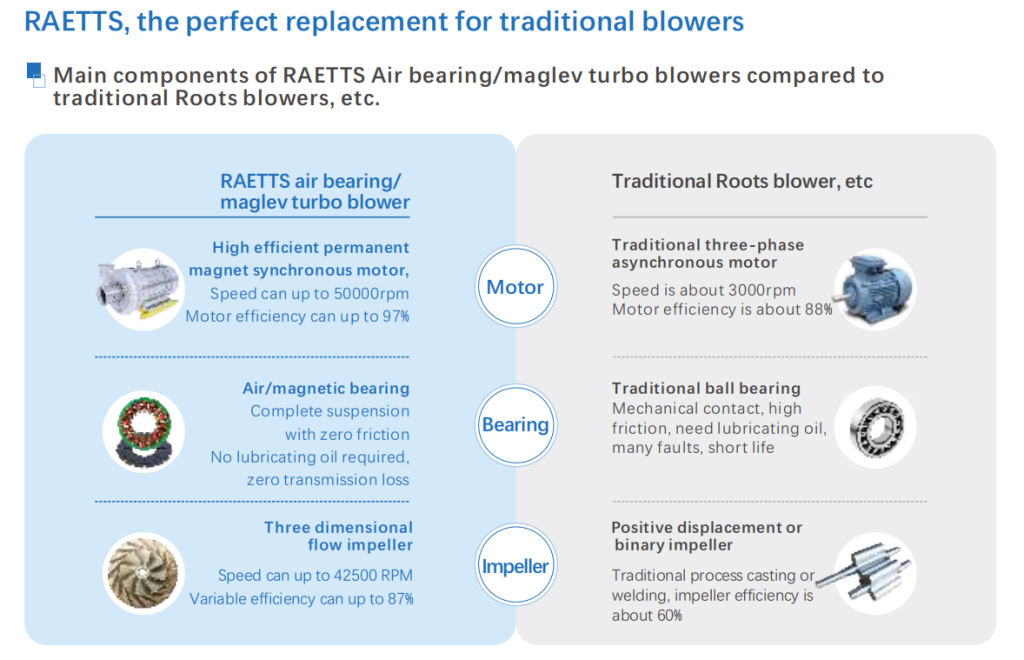

Below is a detailed comparison of the two technologies and why turbo blowers—especially RAETTS air bearing and maglev turbo blowers—have become the global mainstream choice.

⭐ 1. Energy Efficiency: The Most Critical Difference

Turbo Blower (Air Bearing / Maglev)

-

Motor efficiency up to 96% (PMSM motor, 50,000 rpm)

-

Impeller efficiency up to 87% (3D, high-speed centrifugal)

-

Single-stage high-speed compression

-

Real-world energy savings 30–45% vs Roots

Roots Blower

-

Three-lobe positive displacement

-

Motor efficiency ~88% (asynchronous motor, 3,000 rpm)

-

Impeller efficiency ~60%

-

Low compression efficiency → high kWh consumption

⚡ Conclusion:

Turbo blowers deliver significantly higher aeration per kWh, making them the first choice for modern WWTP energy-saving retrofits.

⭐ 2. Maintenance Requirements: Zero vs Heavy

Turbo Blower

-

Air bearing / maglev bearing → no friction, no oil, no wear

-

No gearbox, no belts

-

Maintenance = air filter replacement only

-

Typical yearly maintenance cost: <5% of Roots blower

Roots Blower

-

Requires:

-

Lubricating oil replacement

-

Bearing inspection

-

Belt tension adjustment

-

Long shutdown times for overhaul

-

-

High friction → parts wear quickly

-

Frequent noise, vibration, and overheating issues

🔧 Conclusion:

Turbo blowers are near-zero maintenance machines, drastically reducing downtime and cost.

⭐ 3. Noise Level: Quiet vs Loud

Turbo Blower

-

High-speed but aerodynamic

-

Noise typically ≤80 dB(A) at 1 m

-

Smooth airflow → no pulsation

-

Suitable for indoor, urban, or noise-sensitive plants

Roots Blower

-

Strong pulsation and vibration

-

Typical noise ≥95–105 dB(A)

-

Requires heavy sound insulation

-

Low-frequency noise is difficult to eliminate

🔇 Conclusion:

Turbo blowers are much quieter, improving operator comfort and plant environment.

⭐ 4. Control & DO Stability

Turbo Blower

-

Integrated VFD + PLC

-

Flow & pressure fully adjustable

-

Real-time DO control

-

Ideal for intermittent aeration and variable loads

Roots Blower

-

Limited control range

-

Large DO fluctuations

-

Inefficient during low-load conditions

📈 Conclusion:

Turbo blowers offer superior process stability and support smart wastewater operation.

⭐ 5. Reliability & Service Life

Turbo Blower (RAETTS)

-

No mechanical contact → minimal wear

-

Air bearing: tens of thousands of hours

-

Maglev:

-

Electronic magnetic bearings

-

UFRC imbalance prediction

-

Self-sweeping frequency vibration control

-

Backup safety bearings

-

-

Designed for 20+ years of stable operation

Roots Blower

-

Mechanical contact leads to:

-

Bearing wear

-

Oil leakage

-

Frequent vibration

-

-

Typical lifespan <10 years

-

More downtime over lifecycle

💎 Conclusion:

Turbo blowers are engineered for longer operational life, especially RAETTS maglev systems.

⭐ 6. Air Quality & Environmental Impact

Turbo Blower

-

100% oil-free

-

Zero contamination risk

-

Better for biological treatment processes

Roots Blower

-

Uses oil for lubrication

-

Risk of oil mist entering pipelines

-

Requires frequent environmental checks

🌱 Conclusion:

Turbo blowers support clean operation and align with global low-carbon goals.

⭐ 7. Total Lifecycle Cost (TCO)

When considering:

-

Daily electricity consumption

-

Maintenance downtime

-

Spare parts

-

Service intervals

-

Labor and noise mitigation

Turbo blowers offer 40–60% lower lifecycle cost vs. Roots blowers.

This is why most upgrade projects achieve ROI in 1–3 years.

🎯 Final Conclusion: Why Turbo Blowers Win

| Category | Turbo Blower (Air Bearing / Maglev) | Roots Blower |

|---|---|---|

| Energy Efficiency | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Maintenance | ★ Zero Oil / Zero Friction | ★★★ Frequent & Costly |

| Noise | ⭐⭐⭐⭐ Quiet | ⭐ Loud |

| DO Stability | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Service Life | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Lifecycle Cost | ⭐⭐⭐⭐⭐ | ⭐⭐ |

Turbo blowers—especially RAETTS air bearing and maglev turbo blowers—have become the global standard for wastewater aeration upgrades.

If your plant is still using Roots blowers, you’re paying unnecessary costs every single day.

📩 Interested in upgrading your WWTP blower system?

Contact RAETTS for energy-saving calculations, ROI analysis, and technical selection.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424