Stable WWTP Aeration Upgrade at Oroshaza, Hungary: 2 × 55 kW Maglev Turbo Blowers

As wastewater treatment plants across Europe face increasing pressure to reduce operating costs while maintaining strict process stability and compliance, aeration system upgrades have become one of the most effective optimization measures. Aeration typically represents the largest share of electricity consumption in a wastewater treatment plant, making blower selection a critical long-term decision.

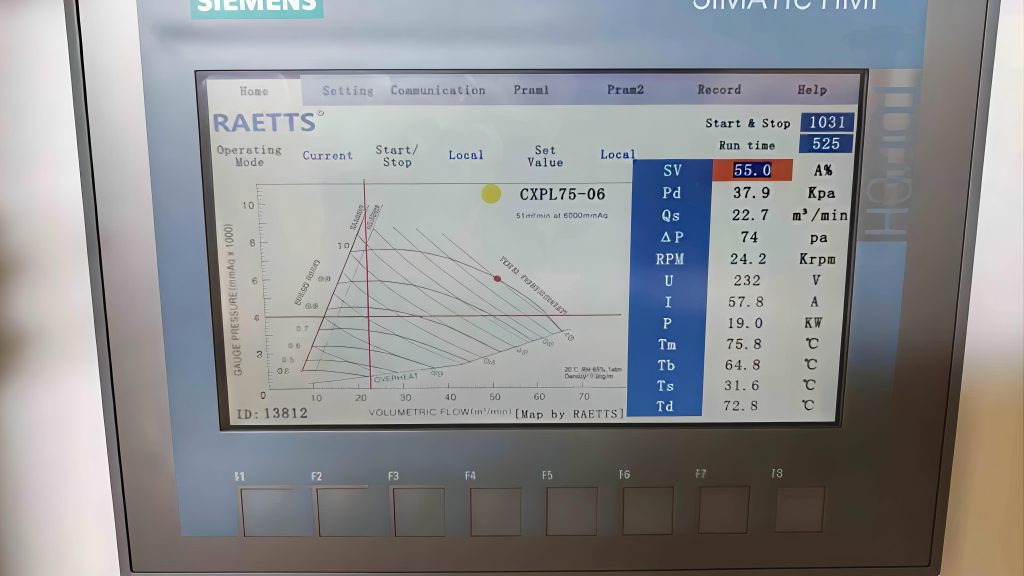

At the Oroshaza Wastewater Treatment Plant (WWTP) in Hungary, RAETTS recently completed an aeration upgrade project with the installation of two 55 kW magnetic levitation turbo blowers. The project focused not only on improving energy efficiency, but more importantly on achieving stable, reliable, and low-maintenance operation suitable for continuous wastewater treatment duty.

Project Background

The Oroshaza WWTP operates under typical European regulatory and environmental requirements, where energy efficiency, noise control, and operational reliability are all essential. The existing conventional blower system had met basic airflow demands, but long-term operation revealed challenges such as higher energy consumption, routine maintenance workload, and operational fluctuations.

To address these issues, the plant selected RAETTS magnetic levitation turbo blowers as part of an aeration system upgrade aimed at reducing OPEX while improving overall process stability.

Solution: Magnetic Levitation Turbo Blower Technology

The upgrade solution consisted of two 55 kW RAETTS maglev turbo blowers, designed specifically for wastewater aeration applications. Unlike traditional blowers, maglev turbo blowers use oil-free, contact-free magnetic bearings, allowing the impeller to rotate at high speed without mechanical friction.

This design eliminates common wear components such as gears, belts, and lubrication systems, resulting in higher efficiency, lower vibration, and simplified maintenance.

Key Performance Results

1. Over 30% Energy Savings

Following commissioning, the Oroshaza WWTP recorded more than 30% reduction in energy consumption compared with the previous conventional blower system under comparable operating conditions. Due to the high efficiency of the maglev technology and its ability to precisely match airflow to process demand, the typical payback period is approximately one year.

2. Excellent Operational Stability

One of the most significant improvements observed after the upgrade was aeration stability. The magnetic levitation design eliminates mechanical contact, which greatly reduces vibration and performance fluctuations during long-term operation.

Stable airflow delivery contributes directly to consistent dissolved oxygen (DO) control, which is essential for biological treatment efficiency and compliance in modern wastewater treatment plants.

3. Ultra-Low Maintenance Cost

Maintenance requirements for the maglev turbo blowers at Oroshaza WWTP are minimal. Annual maintenance cost is estimated at approximately 0.5% of the equipment value, primarily limited to routine air filter replacement.

In comparison, conventional blower systems typically require regular oil changes, bearing inspections, and mechanical servicing, leading to higher maintenance expenses and potential downtime.

4. Low Noise and Vibration

Noise control is an important consideration for many European wastewater treatment facilities. The RAETTS maglev turbo blowers operate at approximately 80 dB, significantly lower than traditional blower technologies.

The ultra-low vibration characteristic of magnetic levitation technology also means that no special foundation or soundproof room is required, simplifying installation and improving the working environment for plant operators.

5. Long Service Life for Continuous Operation

Designed for continuous wastewater duty, RAETTS maglev turbo blowers offer an expected service life of over 20 years. The oil-free, contact-free bearing system minimizes mechanical wear, providing long-term reliability and predictable operation over the equipment lifecycle.

Why Stability Matters in Wastewater Aeration

While energy efficiency is often the primary driver for aeration upgrades, the Oroshaza WWTP project highlights the importance of operational stability. In daily plant operation, stable aeration reduces process fluctuations, minimizes operator intervention, and supports consistent treatment performance.

Magnetic levitation technology delivers this stability by removing the mechanical elements that commonly cause wear, vibration, and performance degradation in conventional blowers.

Conclusion

The installation of two 55 kW RAETTS magnetic levitation turbo blowers at Oroshaza WWTP in Hungary demonstrates how modern aeration upgrades can deliver both immediate and long-term benefits.

With over 30% energy savings, ultra-low maintenance requirements, low noise operation, and a 20+ year service life, maglev turbo blowers provide a practical and proven solution for wastewater treatment plants seeking reliable and sustainable operation.

For WWTP operators considering aeration system upgrades, the Oroshaza project confirms that magnetic levitation technology is not only an advanced option, but a dependable choice for real-world wastewater applications.

About RAETTS

RAETTS specializes in high-efficiency magnetic levitation turbo blowers for wastewater treatment and industrial applications. Our solutions help customers reduce operating costs, improve process stability, and achieve long-term sustainable performance.

Contact RAETTS to learn how maglev turbo blowers can upgrade your aeration system.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424