Lee & Man Paper Chooses RAETTS Maglev Blower for Sustainable Wastewater Treatment

Lee & Man Paper, one of Asia’s top paper manufacturers, has taken a major step toward energy efficiency and sustainability by upgrading its wastewater treatment plant with RAETTS Maglev Turbo Blower technology. This project highlights how paper mills can significantly reduce energy consumption, lower operating costs, and meet environmental targets through blower retrofit.

Project Background

In the wastewater treatment process, aeration is the most energy-intensive stage, often accounting for 50–60% of total electricity consumption. At Lee & Man Paper, the aeration system originally relied on:

-

2 × 110kW Roots blowers (220kW total)

These blowers, while reliable, consumed large amounts of energy and required frequent maintenance due to their oil-lubricated design and mechanical wear.

To modernize operations and cut energy costs, Lee & Man Paper partnered with RAETTS to install a 185kW Maglev Turbo Blower.

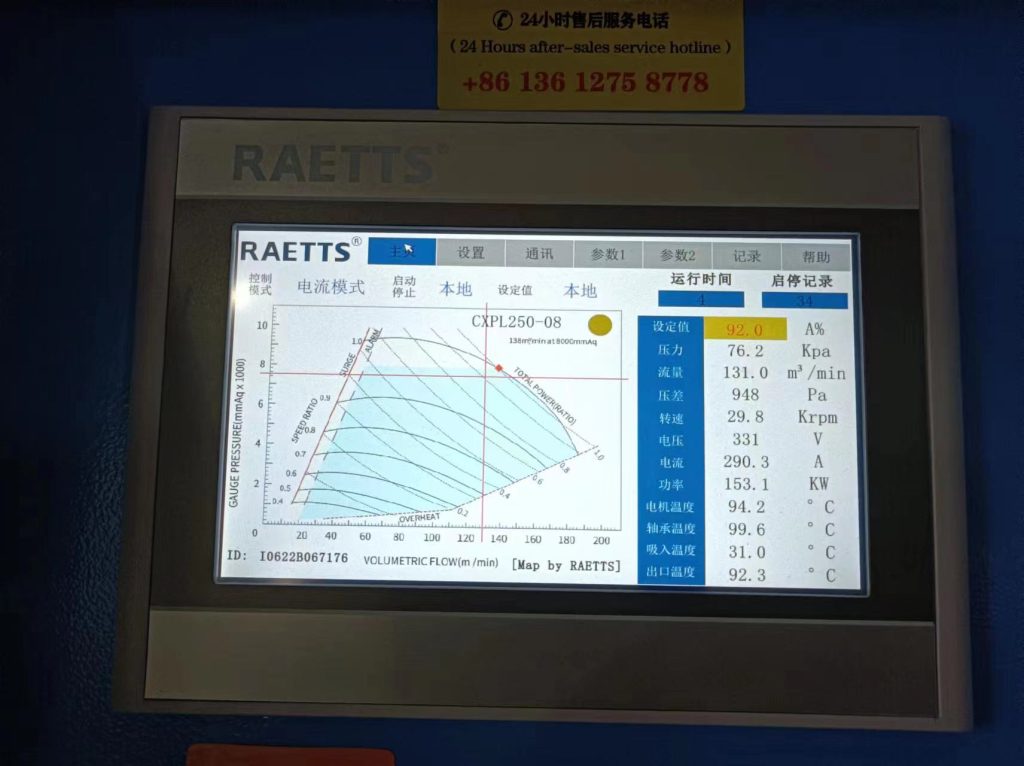

Performance Results

After commissioning, the RAETTS Maglev Blower demonstrated impressive results:

-

Actual operating power: ~150kW

-

Energy savings: ~30% compared to the old Roots blowers

-

Noise level: <80dB, improving the plant environment

-

Payback period: ~12 months

This means that in just one year, the energy savings alone cover the investment cost of the new blower.

Energy Savings Calculation

Here’s a simplified look at the savings:

-

Old Roots setup: 220kW × 8,760 hours/year = ~1,927,200 kWh/year

-

New RAETTS Maglev: 150kW × 8,760 hours/year = ~1,314,000 kWh/year

-

Annual reduction: ~613,200 kWh

At an electricity rate of 0.10 USD/kWh, the plant saves around 61,320 USD per year. That is a substantial cut in operating expenses, especially for a facility running 24/7.

Maintenance & Reliability

Energy efficiency is only part of the story. Roots blowers typically require 5% of equipment value per year in maintenance, including oil changes, belts, and spare parts. In contrast, RAETTS Maglev Blowers are oil-free, bearing-free, and virtually maintenance-free, with costs as low as 0.5% per year.

This not only reduces downtime but also ensures stable performance for over 20 years of service life.

Why Upgrade from Roots to Maglev?

-

High Efficiency: Magnetic levitation technology minimizes friction and energy loss.

-

Smart Control: Variable frequency drive (VFD) allows precise adjustment of airflow, pressure, and dissolved oxygen levels.

-

Compact Footprint: One RAETTS Maglev Blower can replace multiple oversized Roots blowers.

-

Sustainability: Lower carbon emissions and improved compliance with environmental regulations.

Industry Trend

Lee & Man Paper’s project is not an isolated case. Across the paper industry, food & beverage, and municipal wastewater treatment, more operators are shifting from traditional Roots blowers to high-efficiency maglev solutions.

With rising electricity costs and stricter sustainability goals, companies can no longer afford the inefficiencies of outdated blower technology. The transition to maglev systems is both an economic necessity and an environmental responsibility.

Conclusion

The successful installation of the 185kW RAETTS Maglev Turbo Blower at Lee & Man Paper demonstrates the power of innovation in industrial wastewater treatment. By replacing two 110kW Roots blowers, the plant has achieved:

-

30% energy savings

-

Over 60,000 USD annual cost reduction

-

1-year investment payback

-

Long-term reliability with minimal maintenance

RAETTS continues to support global partners in achieving greener, smarter, and more cost-effective operations.

📌 Call to Action

Is your facility still relying on outdated Roots blowers? Now is the time to evaluate maglev technology.

👉 Contact RAETTS today to explore retrofit solutions tailored to your plant.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424