The compressor is the heart of a chiller system. Just like a heart pumps blood through the human body, the compressor pumps refrigerant through the cooling cycle, enabling the chiller to remove heat from water and provide cooling for buildings, industrial processes, or equipment.

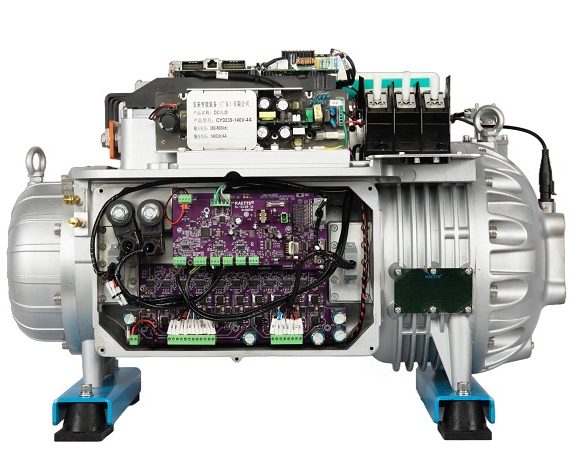

A Maglev compressor (magnetic bearing centrifugal compressor) is an advanced type of compressor used in cooled water chillers and heat pumps. Instead of traditional mechanical bearings or, it uses magnetic bearings to levitate the rotor shaft, eliminating physical contact.

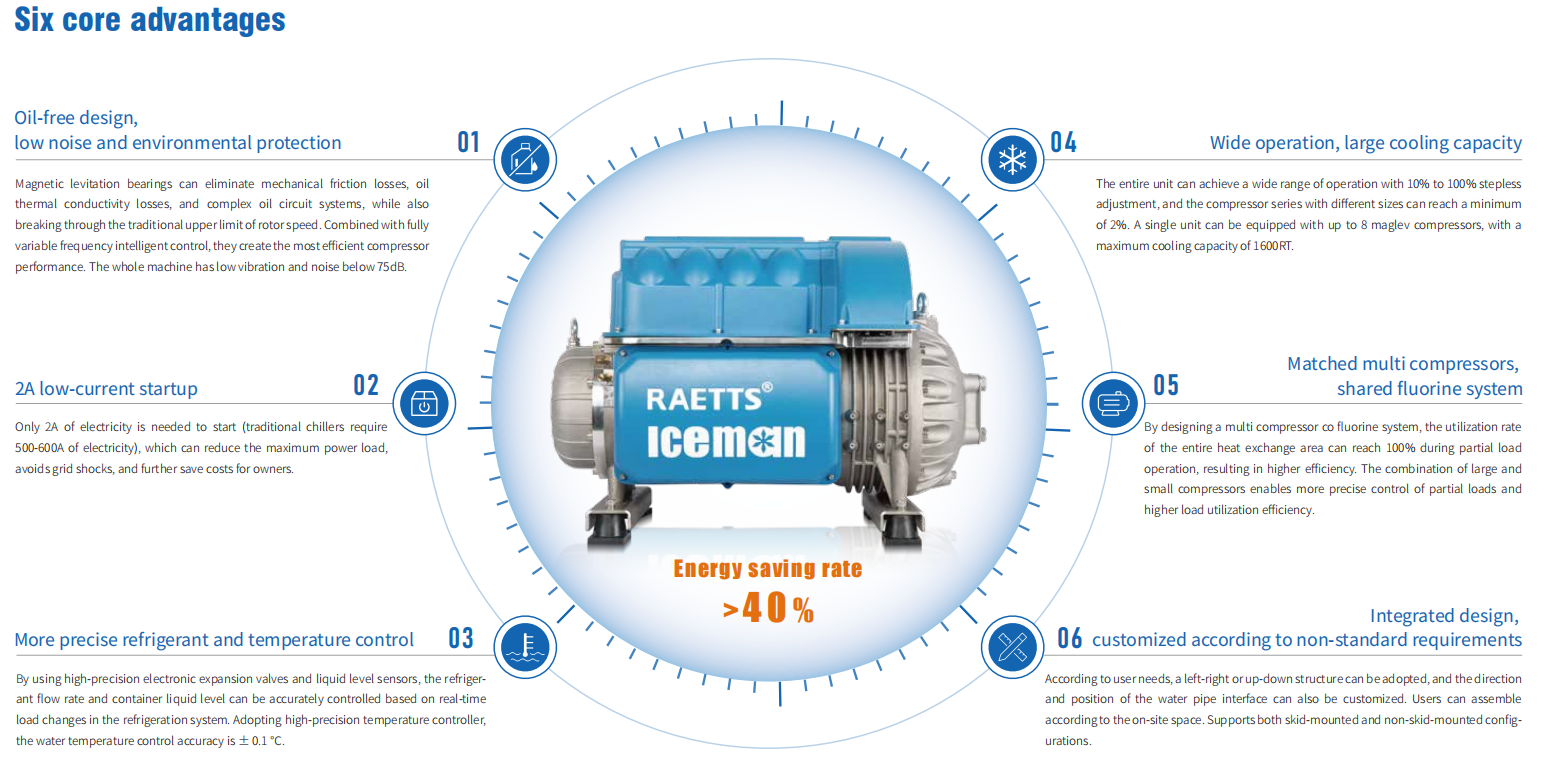

This design provides oil-free, frictionless operation, which significantly improves efficiency and reduces maintenance compared to screw or scroll compressors.

High Efficiency: COP/EER up to 20–40% higher than screw compressors, especially under part-load conditions.

Oil-Free Operation: No lubrication system required → eliminates oil contamination in refrigerant cycle.

Low Noise & Vibration: Quiet operation, suitable for commercial and residential buildings.

Compact & Lightweight: Smaller footprint compared to screw or reciprocating compressors.

Reduced Maintenance: No mechanical wear → lower service costs and longer lifespan.

Smart Control: Seamless integration with building energy management systems.

Magnetic Bearings: The rotor is levitated and stabilized using electromagnetic fields, so there is no mechanical contact.

Variable-Speed Drive: Integrated VFD allows the compressor to precisely adjust speed according to load conditions.

Centrifugal Compression: Refrigerant is accelerated outward by impellers to achieve high compression efficiency.

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)