In the transition to energy-efficient and low-carbon industrial heating systems, industrial heat pumps have become an essential solution. Among the cutting-edge technologies driving this revolution is the magnetic levitation heat pump, offering unmatched efficiency, reliability, and low maintenance in large-scale applications.

Whether in food processing, pharmaceuticals, electronics, or wastewater treatment, magnetic levitation heat pumps are proving to be the next frontier in industrial thermal solutions.

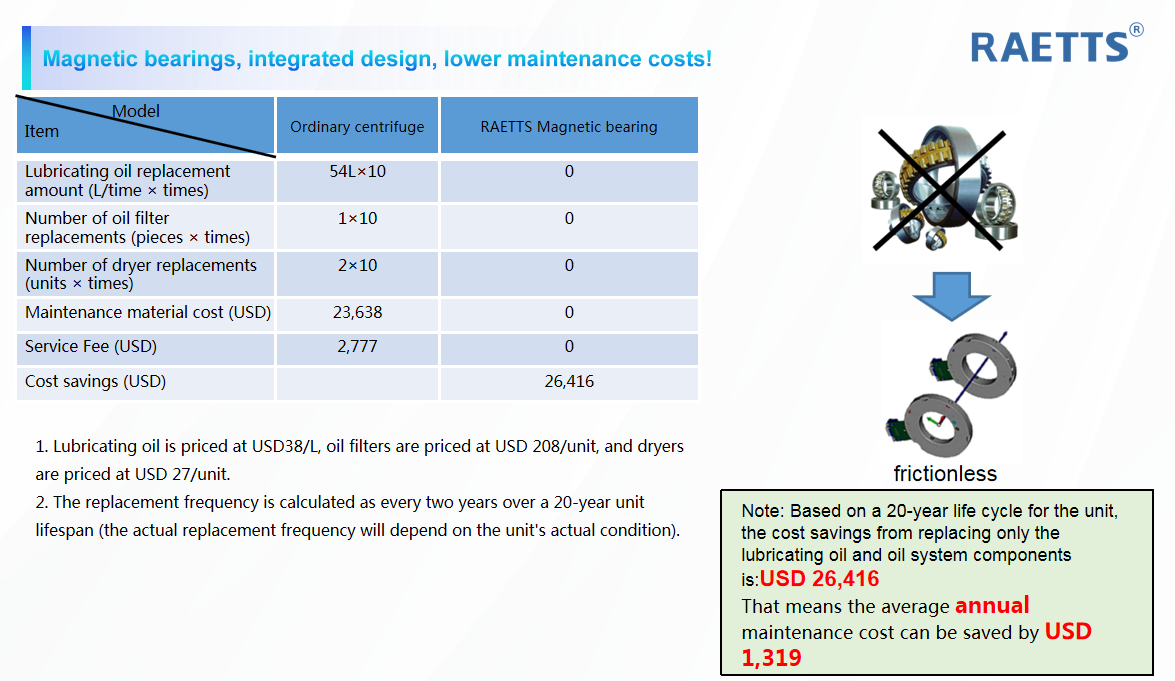

A magnetic levitation heat pump is a type of industrial heat pump that uses oil-free, frictionless magnetic levitation in its centrifugal compressor. This innovation eliminates the need for mechanical contact or lubrication, resulting in:

1.Extremely high energy efficiency

2.Lower operational noise

3.Longer equipment lifespan

4.Minimal heat pump maintenance requirements

At its core, the system operates by transferring heat from a low-temperature source (e.g., water, air, wastewater) to a higher temperature output for process heating or domestic hot water generation.

The first 4-stage magnetic levitation compressor achieve Coefficient of Performance (COP) values exceeding 7.5 in most applications, especially when paired with moderate source temperatures like wastewater or cooling tower return water.

This translates to:

No oil means:

This ensures cleaner operation and higher system reliability.

Thanks to intelligent VFD (Variable Frequency Drive) control, magnetic levitation heat pumps can adapt to real-time thermal loads, maintaining optimal performance across fluctuating conditions.

For example, in a dairy processing plant with seasonal production changes, the heat pump system automatically adjusts compressor speeds and refrigerant flow to maximize efficiency year-round.

Food and beverage processing: 85-95℃ hot water sterilization (pasteurization/UHT); hot water for cleaning, thawing, cooking and other processes (60-85℃), reducing energy consumption by 40-70%.

Textile printing and dyeing processing:Bleaching, dyeing, setting, and drying processes require high-temperature hot water at 80-90°C. This technology can recover waste heat from dyeing wastewater (approximately 30-50°C).

Electroplating and surface treatment:Plating tank heating, pickling, and degreasing require hot water at 70-85°C. Its non-corrosive and oil-free properties make it suitable for harsh environments.

Chemical and pharmaceutical:Reactor heating, raw material drying, and purified water preparation (requiring hot water above 80°C) utilize water-source heat pumps to recover waste heat from cooling water or wastewater, achieving cascade energy utilization.

Plastics and rubber processing:Mold heating and vulcanization processes (requiring hot water at 80-90°C) utilize variable frequency drive capabilities to precisely match temperature fluctuations.

Industrial Waste Heat Recovery: Water-source high-temperature heat pumps recover factory cooling water (30-45°C), flue gas waste heat (40-60°C), or geothermal tailwater, heating it to 80-90°C for direct use in production, thus increasing waste heat value.

Steam System Complementary/Substitution: 90°C hot water is generated to replace low-pressure steam for heating or process applications (such as cleaning and preheating), reducing boiler load.

Agricultural Use: 70-80°C hot water is output from greenhouses for heating via floor heating or fan coil units, suitable for winter planting in cold regions. It also provides constant temperature heating for livestock farms and livestock insulation (requires high-temperature hot water circulation) without the risk of gas leaks. It can be used for drying grain, medicinal herbs, fruits, and vegetables (hot air temperature 60-85°C), saving over 50% energy compared to coal-fired drying and is pollution-free.

Northern Coal-to-Electricity/Clean Heating: Replaces coal-fired boilers to provide heating water above 75°C for older residential communities, schools, and hospitals (especially suitable for radiator system retrofits).

Hotels/Hospitals/Swimming Pools: Provides high-temperature domestic hot water (60-85°C) or constant-temperature swimming pool water, avoiding the drawback of conventional heat pumps requiring auxiliary electric heating. Suitable for hospital surgical instrument sterilization and laundry steam preheating (90°C hot water partially replaces steam).

Regional Energy Station: Serves as a distributed heat source, providing a high-temperature hot water network for industrial parks, integrating renewable energy sources such as solar energy and wastewater heat.

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)