Maglev Turbo Blowers Are Replacing Roots Blowers in wastewater treatment aeration

With rising electricity prices and increasingly strict energy-efficiency requirements, wastewater treatment plants worldwide are rethinking their aeration systems. Aeration typically accounts for 50–70% of total energy consumption in a wastewater treatment plant, making blower selection a critical decision.

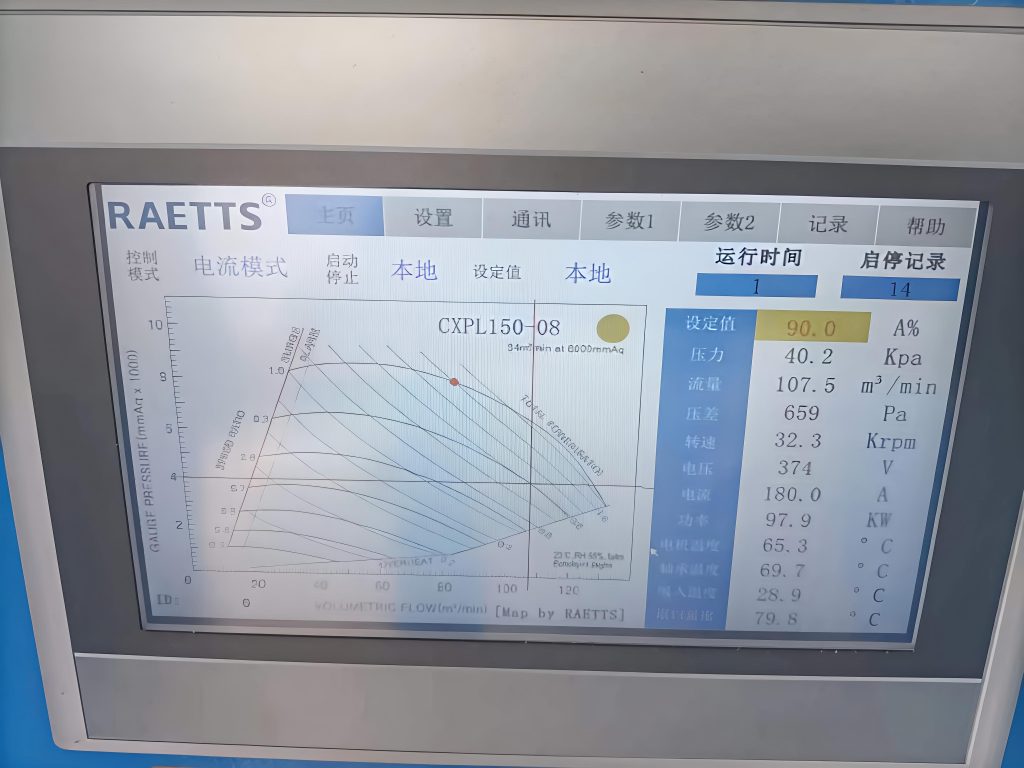

In recent years, maglev turbo blowers have emerged as a new-generation solution, rapidly replacing traditional Roots blowers. A recent project by RAETTS at a wastewater treatment plant in Ruijin, Jiangxi Province, China, clearly demonstrates why this shift is happening.

Three 110 kW RAETTS maglev turbo blowers were successfully installed and commissioned, delivering stable operation, significant energy savings, and fast return on investment.

Project Background: Ruijin Wastewater Treatment Plant

The Ruijin wastewater treatment plant required a reliable aeration upgrade to reduce operating costs while maintaining stable dissolved oxygen (DO) control. The plant had previously relied on conventional Roots blowers, which are known for high energy consumption, frequent maintenance, and noise.

RAETTS proposed a solution using three 110 kW magnetic levitation turbo blowers, designed for continuous aeration duty and intelligent airflow control. Since commissioning, the system has operated smoothly with excellent performance feedback from the plant operator.

What Is a Maglev Turbo Blower?

A maglev turbo blower uses magnetic levitation bearings instead of mechanical bearings. The impeller is fully suspended in a magnetic field, allowing it to rotate at extremely high speeds without physical contact.

This oil-free, contact-free design eliminates friction and mechanical wear, resulting in higher efficiency, longer service life, and lower maintenance requirements.

Key Advantages of Maglev Turbo Blowers in Wastewater Aeration

1. Over 30% Energy Savings Compared with Roots Blowers

In the Ruijin project, the maglev turbo blowers achieved more than 30% energy savings compared with traditional Roots blowers operating under similar airflow and pressure conditions.

Roots blowers rely on positive displacement and constant-speed operation, which makes them inefficient under variable load conditions. In contrast, maglev turbo blowers use high-speed variable-frequency control, precisely matching airflow to real-time oxygen demand.

2. Ultra-High Stability and Reliability

Maglev turbo blowers feature:

- No mechanical contact

- No lubrication oil

- No gearbox

- No belt transmission

This design significantly reduces vibration and eliminates common failure points found in Roots blowers. For wastewater plants that require 24/7 continuous operation, stability is a major advantage.

3. Extremely Low Maintenance Cost

Traditional Roots blowers require regular maintenance, including:

- Gearbox oil changes

- Bearing replacement

- Seal inspection

- Frequent overhauls

Maglev turbo blowers remove most of these tasks. With no oil system and minimal wear, maintenance is largely limited to periodic inspections and filter replacement. This dramatically lowers long-term operating costs and reduces unplanned downtime.

4. Fast Payback Period – Around 1 Year

Thanks to high energy efficiency and reduced maintenance expenses, the typical payback period for a maglev turbo blower is around one year.

In regions with higher electricity prices, the ROI can be even faster. For plant operators and municipalities, this makes maglev technology not only an engineering upgrade but also a strong financial decision.

5. Long Service Life up to 20 Years

RAETTS maglev turbo blowers are designed for a service life of up to 20 years. The absence of mechanical wear components significantly extends equipment lifespan compared with Roots blowers, which often require major refurbishment after several years of operation.

6. Intelligent Control for Modern Aeration Systems

Maglev turbo blowers integrate advanced control systems that support:

- Real-time airflow adjustment

- DO-based control

- Remote monitoring

- Smart plant integration

This makes them ideal for modern wastewater treatment plants pursuing digitalization, automation, and carbon reduction goals.

Maglev Turbo Blower vs. Roots Blower: A Clear Comparison

| Item | Maglev Turbo Blower | Roots Blower |

|---|---|---|

| Energy Efficiency | Very High | Low |

| Maintenance | Very Low | High |

| Noise & Vibration | Very Low | High |

| Service Life | Up to 20 years | Shorter |

| ROI | ~1 year | Long or unclear |

The comparison clearly shows why more wastewater plants are choosing maglev technology for aeration upgrades.

Do We Still Need Roots Blowers?

For modern wastewater treatment plants facing rising energy costs, stricter environmental regulations, and labor constraints, the answer is becoming increasingly clear.

Maglev turbo blowers represent the most advanced, intelligent, and energy-efficient aeration technology available today.

With proven performance in projects like the Ruijin wastewater treatment plant, maglev blowers are no longer a future concept—they are the present solution.

So the real question is:

For today’s aeration systems, do we still need Roots blowers?

About RAETTS

RAETTS specializes in high-speed magnetic levitation turbo blowers for wastewater treatment and industrial applications. Our solutions help customers reduce energy consumption, lower operating costs, and achieve long-term sustainable operation.

Contact RAETTS to learn how maglev technology can upgrade your aeration system and deliver measurable savings.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424