RAETTS Successfully Upgrades AB InBev Sichuan Brewery with Energy-Efficient Turbo Blowers

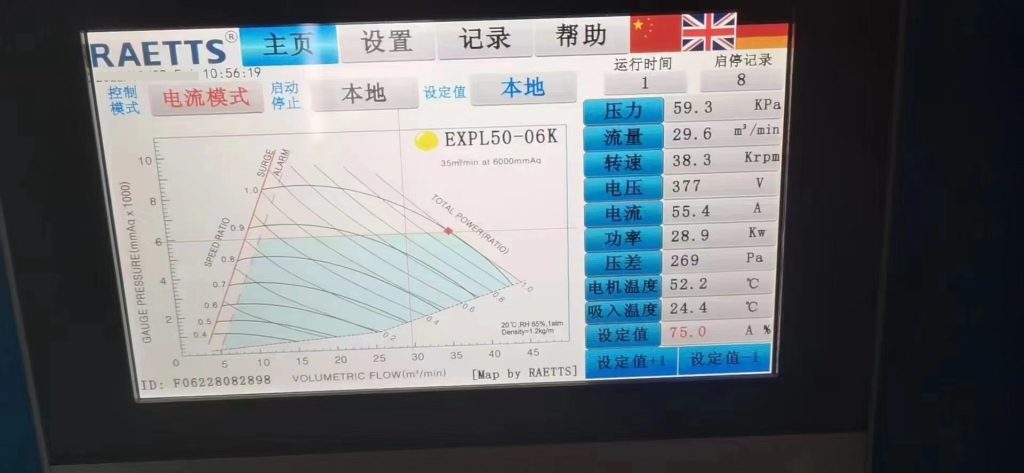

RAETTS, a global leader in advanced air supply and energy-saving technologies, has successfully completed an energy-efficiency retrofit project for AB InBev’s Sichuan Brewery (Budweiser). Two 37kW air bearing turbo blowers were delivered, installed, and commissioned, replacing the site’s traditional Roots blowers previously used in the wastewater treatment plant.

This project marks another milestone in RAETTS’ continued collaboration with leading beverage companies, helping them achieve sustainability goals, energy efficiency, and operational excellence.

The Challenge: Outdated and Inefficient Roots Blowers

AB InBev Sichuan Brewery, one of the company’s major brewing facilities in China, relies on an on-site wastewater treatment system to ensure compliance with strict environmental discharge standards. However, the existing Roots blowers had been in operation for years and posed several challenges:

-

High energy consumption due to low efficiency.

-

Frequent maintenance and unexpected downtime.

-

Noise and vibration issues, impacting the plant environment.

-

Limited ability to adjust air supply based on real-time process needs.

With the brewery’s growing production and increasing focus on sustainability, AB InBev sought a modern, high-efficiency blower solution.

The RAETTS Solution: Air Bearing Turbo Blowers

RAETTS provided a customized upgrade plan and recommended the installation of two 37kW air bearing turbo blowers. Compared to conventional Roots blowers, RAETTS turbo blowers bring:

-

Energy Savings up to 30–40% – thanks to high-speed permanent magnet motors and advanced aerodynamics.

-

Oil-Free, Low-Maintenance Operation – air bearing technology eliminates the need for lubrication, reducing maintenance costs.

-

Low Noise and Vibration – improving the working environment within the plant.

-

Smart Control & Flexibility – variable frequency operation allows precise adjustment of air supply to match wastewater treatment demands.

Project Execution and Results

The retrofit project was completed within a short installation window to minimize disruption to brewery operations. RAETTS engineers worked closely with AB InBev’s technical team, ensuring a smooth replacement of the old Roots blowers.

Since commissioning, the new RAETTS turbo blowers have demonstrated stable operation and significant energy reduction, directly lowering the brewery’s operational costs and carbon footprint. According to preliminary data, the upgrade is expected to generate annual electricity savings of more than 120,000 kWh, equivalent to reducing CO₂ emissions by over 100 tons per year.

Driving Sustainability in the Beverage Industry

AB InBev, the world’s largest brewer, has committed to ambitious sustainability goals, including reducing water usage, cutting CO₂ emissions, and improving energy efficiency across its operations. RAETTS’ energy-saving blower technology aligns perfectly with these objectives, enabling breweries to modernize their wastewater treatment systems without compromising performance.

This project also sets a benchmark for other beverage companies in China and beyond, showcasing how technological upgrades can deliver both economic and environmental benefits.

About RAETTS

RAETTS is a leading manufacturer of maglev turbo blowers, air bearing turbo blowers, and high-speed centrifugal blowers, serving industries such as wastewater treatment, aquaculture, food & beverage, cement, and electronics. With a strong focus on innovation, energy efficiency, and customer service, RAETTS continues to support global industries in achieving green transformation and sustainable growth.

👉 Want to learn more about how RAETTS can support your wastewater treatment projects? Contact us today to explore customized Maglev Blower solutions.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424