💧 RAETTS Air Bearing Blowers Help Xinjiang Wastewater Treatment Plant Achieve 30%+ Energy Savings

1️⃣ Project Background

The wastewater treatment plant located in Xinjiang, China, had been relying on conventional Roots blowers for its aeration system for many years. While the Roots technology was once widely adopted, it has several inherent disadvantages — such as low energy efficiency, high vibration, frequent maintenance, and oil contamination risks.

As the plant’s operation expanded, these issues began to affect both process stability and operational costs. Power consumption continued to rise, and maintenance downtime became a burden for operators. The plant management decided it was time for a comprehensive energy-saving upgrade that could reduce electricity usage, improve system automation, and ensure stable dissolved oxygen (DO) levels in aeration tanks.

With these goals in mind, the operator turned to RAETTS, a leading manufacturer of high-efficiency air bearing and maglev turbo blowers, known for their reliability, intelligence, and proven results in wastewater treatment applications worldwide.

2️⃣ RAETTS Solution

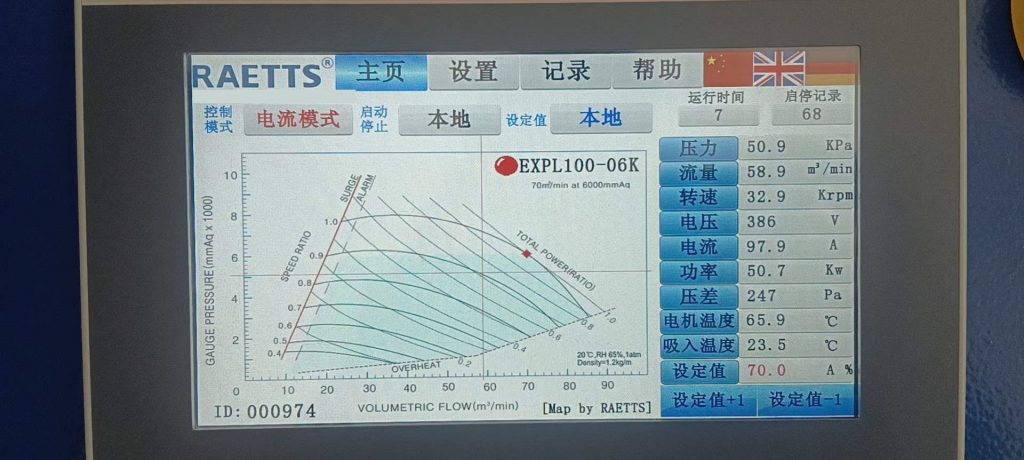

After a detailed on-site evaluation, RAETTS recommended replacing the existing Roots blowers with two 75kW RAETTS Air Bearing Turbo Blowers. This advanced technology integrates high-speed permanent magnet motors, air foil bearings, and built-in variable frequency control, allowing precise and efficient aeration tailored to real-time process demands.

Key features of RAETTS Air Bearing Turbo Blowers include:

-

Oil-free design: No lubrication or gear transmission, ensuring 100% clean air and zero risk of oil contamination.

-

High-speed permanent magnet motor: Compact structure with strong torque, enabling efficient operation under varying load conditions.

-

Smart control system: Supports automatic adjustment by DO, pressure, or flow rate, allowing real-time optimization of aeration performance.

-

Low noise and vibration: Thanks to the air bearing design, operation is extremely quiet and stable, creating a better working environment for operators.

-

Easy installation and maintenance: Modular design allows quick setup and minimal maintenance compared with Roots blowers.

The two RAETTS 75kW air bearing blowers were commissioned in the main aeration basin of the Xinjiang wastewater treatment plant. The installation was completed smoothly, requiring minimal modification to the existing piping and control system.

3️⃣ Results & Performance

Since commissioning, both units have performed beyond expectations. Under actual process conditions, the real operating power of each blower is only around 50kW, instead of the rated 75kW. This represents a 30–35% reduction in energy consumption compared with the original Roots blowers.

The benefits were immediate and measurable:

✅ Significant Energy Savings – The plant’s total electricity cost for aeration dropped substantially, resulting in a payback period of less than 2 years.

✅ Improved Aeration Efficiency – The air flow and pressure are now more stable, ensuring optimal DO levels and better biological treatment performance.

✅ Maintenance-Free Operation – With no oil, belts, or gears, the air bearing system requires almost no maintenance, reducing O&M workload and downtime.

✅ Noise Reduction – Sound levels in the blower room decreased by more than 15 dB, greatly improving the on-site working environment.

✅ Environmental Benefits – The oil-free and energy-efficient design helps reduce carbon emissions, aligning with China’s national goals for green, low-carbon operations.

Plant operators have praised the blowers for their smooth start-up, quiet performance, and intelligent control features that simplify daily operation. The system’s built-in monitoring allows remote data viewing and trend analysis, giving O&M teams full visibility of performance and efficiency.

4️⃣ Customer Feedback & Future Outlook

The management team at the Xinjiang wastewater plant expressed strong satisfaction with the project results. They noted that energy bills dropped noticeably in the first month after installation, while the aeration system maintained excellent process stability.

Encouraged by these results, the plant is now considering extending the upgrade to its secondary treatment area and recommending RAETTS technology for other regional facilities.

This project further demonstrates how RAETTS Air Bearing Turbo Blowers can effectively replace traditional Roots blowers in wastewater treatment, helping operators achieve high efficiency, reliability, and sustainability with measurable cost reductions.

💡 Conclusion

Through this successful project in Xinjiang, RAETTS once again proves its commitment to innovation and energy efficiency in the water industry. By providing cutting-edge air bearing technology, RAETTS helps wastewater treatment plants around the world achieve smarter, greener, and more cost-effective operations.

RAETTS — Powering the Future of Clean Water with Smart Blower Technology.

#WastewaterTreatment #EnergySaving #AirBearingBlower #RAETTS #Sustainability #WaterIndustry #SmartOperation #RootsBlowerReplacement

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424