RAETTS Air Bearing Blowers Help Thai Paper Mill Cut Energy Costs and Boost Wastewater Treatment Efficiency

Introduction

The paper industry is known for its high energy consumption and demanding wastewater treatment requirements. Traditional blowers, such as roots blowers and screw blowers, often bring challenges like excessive electricity usage, frequent maintenance, and oil contamination risks.

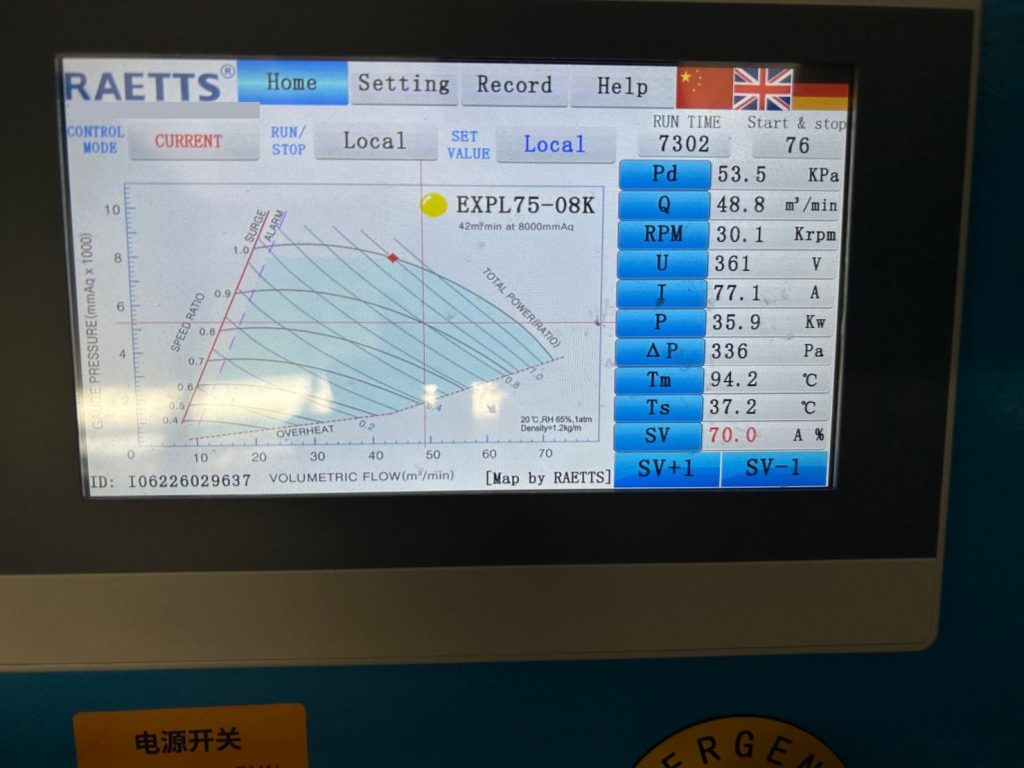

Recently, a leading paper mill in Thailand turned to RAETTS Air Bearing Blower technology to upgrade its wastewater treatment process. By installing one 55 kW air bearing blower and one 22 kW portable air bearing blower, the mill is now achieving significant energy savings and improved operational reliability.

Why Paper Mills Face Challenges in Wastewater Treatment

Paper mills consume large volumes of water in their production process. This results in wastewater with high organic load and solid particles that must be treated before discharge. To maintain aeration and biological treatment efficiency, blowers play a critical role.

However, traditional blowers often create problems:

-

⚡ High energy consumption – electricity costs can account for more than 40% of treatment expenses.

-

🛠️ Frequent maintenance – bearings and lubrication systems require downtime and costly repairs.

-

🛢️ Oil contamination risk – traditional lubrication systems can compromise water quality and add treatment complexity.

For mills seeking cost reduction and sustainability, the choice of blower technology is decisive.

The RAETTS Solution in Thailand

In this Thai paper mill project, RAETTS provided:

-

1 × 55 kW Air Bearing Blower – as the main aeration powerhouse for wastewater treatment tanks.

-

1 × 22 kW Portable Air Bearing Blower – a flexible unit used for supplemental aeration and emergency backup.

Key Advantages Delivered:

-

30–40% Energy Savings

Air bearing technology eliminates mechanical friction, significantly improving efficiency compared with roots and screw blowers. -

Oil-Free Operation

The blowers run without lubricating oil, ensuring zero contamination risk in wastewater treatment. -

Low Maintenance, High Reliability

With no contact bearings, RAETTS blowers achieve long service life and almost maintenance-free operation. -

Compact & Flexible Design

Especially with the 22 kW portable unit, the mill gains flexibility in handling seasonal demand fluctuations.

Why the Paper Mill Chose RAETTS

The decision was driven by a clear ROI (Return on Investment):

-

The projected payback period for energy savings is less than 2 years.

-

Reduced downtime means more stable wastewater treatment and compliance with strict environmental regulations.

-

RAETTS provided full technical support, from system design to installation and commissioning.

As a result, the Thai paper mill now operates with lower costs, higher efficiency, and improved sustainability credentials — positioning itself as a forward-thinking leader in the industry.

The Bigger Picture: Sustainability in Paper Manufacturing

The shift from traditional blowers to high-efficiency, oil-free air bearing blowers aligns with global trends in sustainable manufacturing. Paper mills worldwide are under pressure to reduce carbon emissions, cut operating costs, and meet stricter wastewater discharge standards.

RAETTS technology is already supporting paper plants, wastewater treatment facilities, aquaculture farms, and food processing industries across Asia, Europe, and the Americas.

Conclusion

The Thai paper mill’s adoption of RAETTS Air Bearing Blowers highlights the future of industrial wastewater treatment: efficient, clean, and reliable aeration solutions.

For paper mills looking to lower electricity bills, reduce maintenance, and ensure compliance, RAETTS stands out as the trusted partner.

👉 Ready to upgrade your plant’s efficiency? Contact RAETTS today and discover how air bearing technology can transform your operations.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424