Aeration is the heart of wastewater treatment—and also its biggest energy consumer. Studies consistently show that aeration systems account for 30–60% of a plant’s total electricity use. This makes blowers the prime target for efficiency improvements.

Modern blower systems that integrate a Variable Frequency Drive (VFD) and a Programmable Logic Controller (PLC) panel are now recognized as game-changers. They provide not only energy efficiency but also process stability and long-term cost savings.

On-demand air supply: VFD allows the blower to run at variable speeds, precisely matching the required airflow.

Measured savings: Case studies show 20–40% lower energy consumption compared to fixed-speed blowers operating with throttling.

Soft start & reduced stress: VFD minimizes inrush current during startup, reducing motor stress and extending equipment life.

DO control integration: The PLC receives dissolved oxygen (DO) sensor data and automatically adjusts blower output, preventing over- or under-aeration.

Multi-unit coordination: PLC panels can manage multiple blowers in rotation or backup mode, ensuring redundancy and optimal load sharing.

Quick response to load changes: Ideal for handling variable influent flow and organic load conditions.

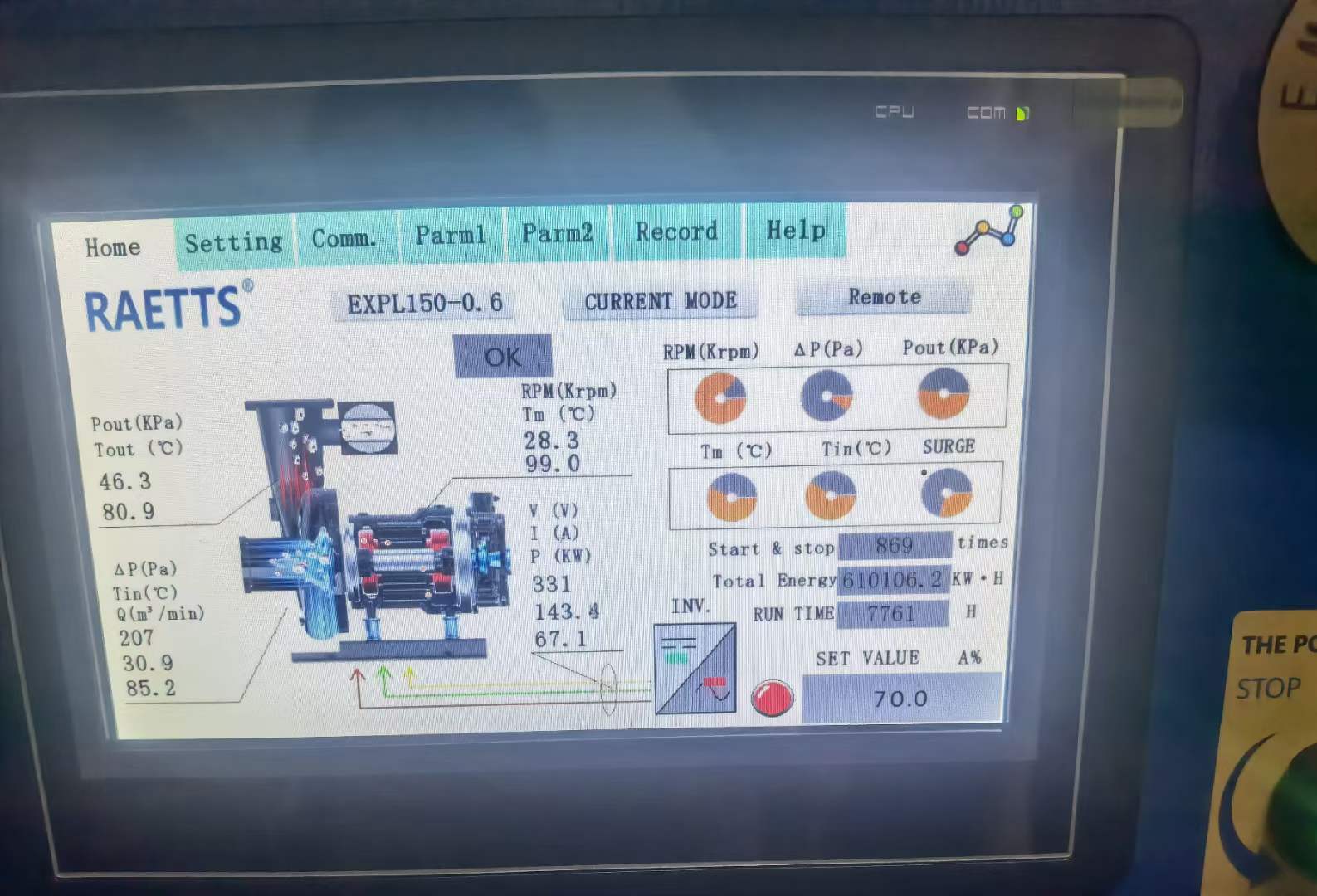

Real-time monitoring: Parameters like current, pressure, airflow, and temperature are tracked and displayed on the PLC HMI.

Automated alarms & fault diagnosis: Operators receive instant alerts for deviations, reducing downtime.

Predictive maintenance: Data logging helps identify wear patterns before failures occur.

Extended equipment lifetime: Smooth, variable-speed operation reduces mechanical stress.

Upgrading to blowers equipped with VFD and PLC panels is not just an equipment change—it is a shift towards smart, efficient, and sustainable wastewater operations. The measurable benefits in energy savings, process stability, and reduced maintenance directly support both OPEX reduction and net-zero goals.

For utilities aiming to modernize, the question is no longer if they should adopt VFD and PLC blowers, but when.

Feel free contact us to discuss how to upgrade your equipments.

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)