The “Heart” of Municipal Wastewater Treatment: Why Choosing the Right Blower Matters

In every municipal wastewater treatment plant, the blower is often described as the “heart of the process.” Just as the human heart pumps blood to sustain life, blowers provide the oxygen necessary for microorganisms to break down organic pollutants in wastewater. Their performance directly impacts aeration efficiency, energy costs, and the long-term stability of the treatment system.

However, the importance of blowers is sometimes underestimated. Behind the scenes, these machines operate 24 hours a day, 365 days a year, without interruption. The demands on them are enormous, and the choice of technology can determine whether a plant runs efficiently or struggles with high costs and frequent downtime.

Challenges with Traditional Blowers

For decades, wastewater plants have relied on traditional positive displacement and conventional centrifugal blowers. While proven in design, these systems often face major drawbacks in today’s environment of rising energy costs and stricter sustainability goals:

-

High energy consumption – Blowers can account for 40–60% of total plant electricity use, making them the single largest energy consumer in wastewater treatment.

-

Excessive noise levels – Traditional blowers are notoriously loud, creating challenging working conditions for plant staff and sometimes requiring additional noise control measures.

-

Frequent maintenance – Components such as belts, bearings, and lubricated gears require regular attention, leading to downtime and added costs.

-

Limited efficiency at variable loads – Many conventional blowers struggle to maintain high efficiency when plant aeration demand fluctuates.

These challenges highlight why forward-looking utilities are actively seeking more advanced solutions.

The Need for Innovation in Municipal Wastewater Treatment

Municipal wastewater treatment is a mission-critical service. Plants must operate continuously to protect water resources, public health, and the environment. At the same time, operators face mounting pressure to:

-

Reduce operating costs in the face of rising electricity prices.

-

Lower carbon emissions to meet sustainability and government targets.

-

Ensure reliability with equipment that runs around the clock.

This makes innovation not just desirable, but essential. The blower technology of yesterday cannot fully meet the challenges of today.

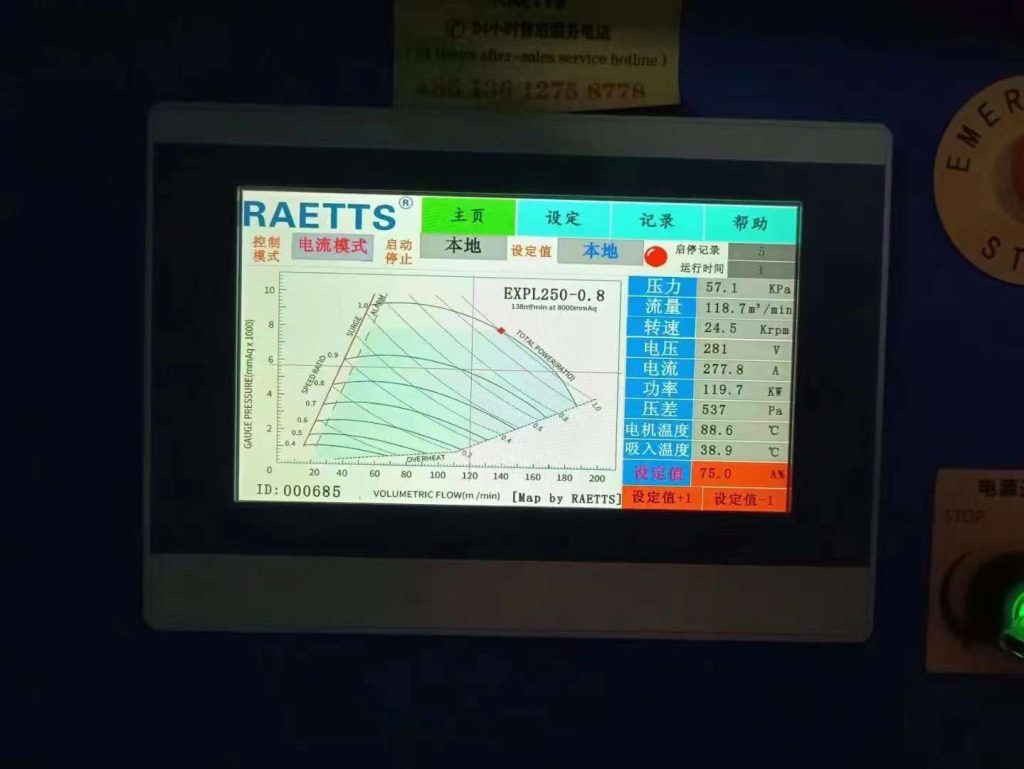

RAETTS Air Bearing Turbo Blowers: Redefining Efficiency and Reliability

As a global leader in high-efficiency blower technology, RAETTS has pioneered the application of magnetic levitation turbo blowers in municipal wastewater treatment. By combining advanced aerodynamics with magnetic bearing technology, RAETTS offers a solution that directly addresses the shortcomings of traditional blowers.

Key advantages include:

-

Ultra-high energy efficiency – Maglev turbo blowers operate at high speeds with minimal friction, delivering up to 30–40% energy savings compared with traditional technologies.

-

Low noise operation – With no mechanical contact inside the bearing system, vibration and noise are dramatically reduced.

-

Zero lubrication and minimal maintenance – Magnetic bearings eliminate the need for oil, gears, or belts, reducing maintenance downtime.

-

Smart control system – Designed for variable load operation, RAETTS blowers automatically adjust to real-time aeration demand, ensuring optimal performance at all times.

-

Proven reliability – Built for continuous 24/7 operation, these blowers have been successfully installed in municipal projects worldwide, earning recognition for both performance and durability.

Case in Point: Municipal Wastewater Plants Worldwide

RAETTS maglev turbo blowers have been deployed across Asia, Europe, and the Americas, providing reliable aeration for thousands of cubic meters of wastewater every day. Municipalities report not only significant reductions in electricity bills but also improved process stability and quieter operating environments for their staff.

For example, in recent installations, plants have documented:

-

Energy savings exceeding 35% compared to their old systems.

-

Reduced maintenance interventions thanks to oil-free, contact-free design.

-

Quick return on investment (ROI), often within 2–3 years, driven by lower energy and service costs.

Looking Ahead: The Future of Wastewater Treatment Blowers

As cities continue to grow and environmental standards become stricter, the need for reliable, efficient, and sustainable blower technology will only intensify. Traditional blowers will increasingly give way to advanced solutions that combine energy efficiency, smart control, and long service life.

RAETTS stands at the forefront of this transition, providing municipal operators with not just equipment, but a pathway to sustainable and cost-effective wastewater treatment.

Conclusion

In municipal wastewater treatment, blowers are far more than just another piece of equipment—they are the beating heart of the process. With rising energy prices and environmental targets, utilities can no longer afford to overlook blower efficiency and reliability.

By adopting RAETTS maglev turbo blowers, municipal plants can significantly reduce energy costs, minimize maintenance, and ensure stable, around-the-clock operation. The future of wastewater treatment is already here—and it’s powered by magnetic levitation.

E-mail: sales@raettsgroup.com

WhatsApp: +86 13631730102