How RAETTS Blower Helped a Wastewater Plant Save USD 14,800 in Annual Electricity Costs

Introduction

Energy consumption has always been one of the biggest challenges in wastewater treatment plants. Aeration blowers, which run 24/7, typically account for 40–60% of the total energy usage in such facilities. Replacing inefficient equipment with high-efficiency blowers is one of the fastest ways for operators to reduce operational costs and meet stricter environmental standards.

RAETTS recently partnered with a wastewater treatment plant in Zhejiang Province, China, to deliver a successful energy-saving upgrade project. By replacing a traditional Roots blower with RAETTS air suspension blower technology, the plant not only cut energy consumption dramatically but also achieved a full return on investment in less than one year.

Project Background

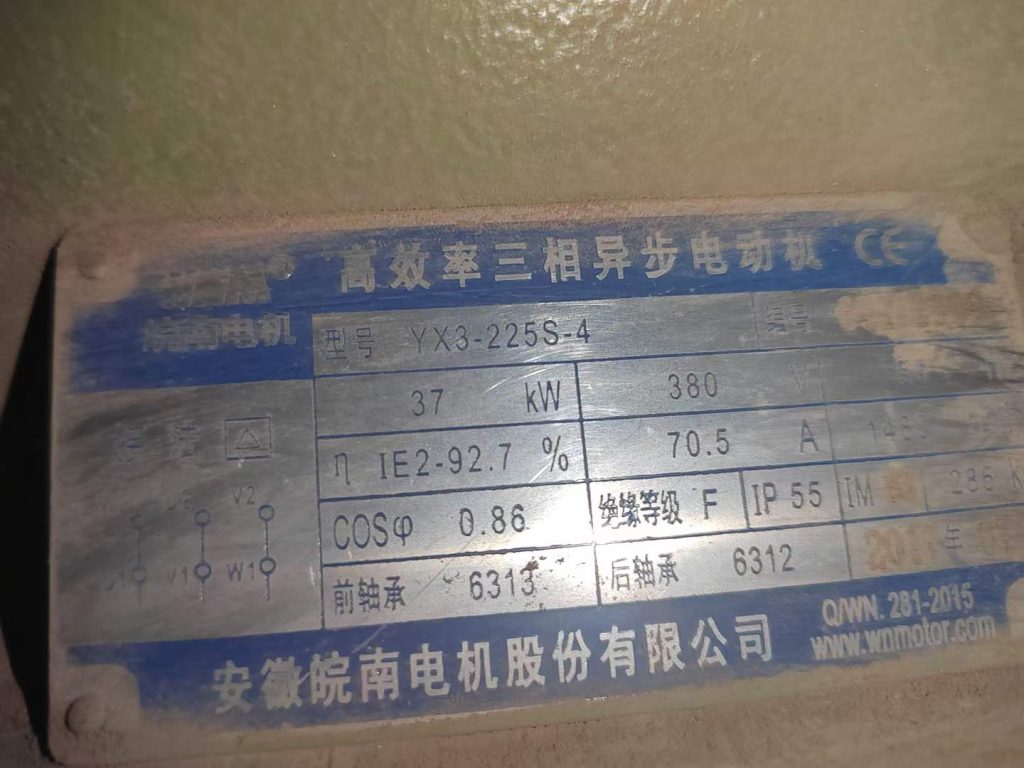

The Zhejiang wastewater treatment facility had been relying on a 37 kW Roots blower for aeration. While effective, the blower had several disadvantages:

-

High energy consumption

-

Significant noise and vibration

-

Frequent maintenance requirements

-

Rising electricity costs

To improve operational efficiency and reduce costs, the plant decided to explore new blower technologies. After technical evaluation, RAETTS was selected to supply two 22 kW air suspension blowers (configured as 1 in operation + 1 standby) for the aeration system.

Technical Upgrade & Implementation

The plant’s engineering team, together with RAETTS specialists, replaced one of the existing Roots blowers with a RAETTS 22 kW air suspension blower.

Key implementation details:

-

Configuration: 1 operating blower, 1 standby blower

-

Replacement: One 37 kW Roots blower replaced by a 22 kW RAETTS blower

-

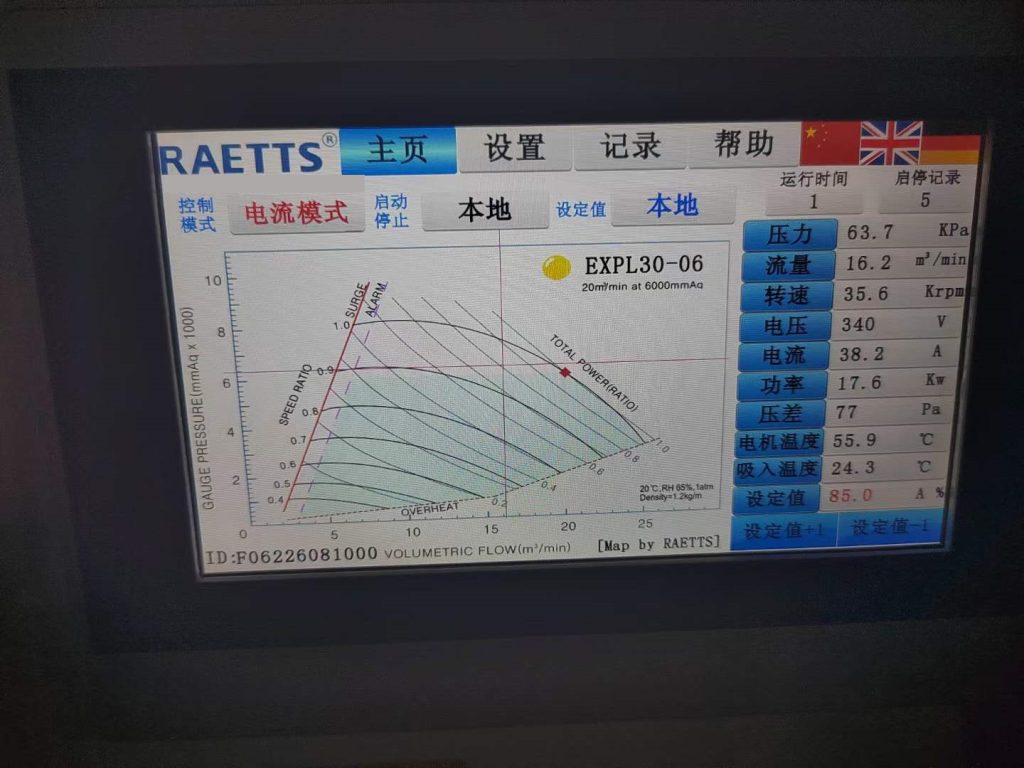

Operation test result: Actual running power measured at 17.6 kW

This result was particularly striking: not only did the RAETTS blower consume far less rated power, but the real-time energy draw was even lower than expected.

Measured Results & Cost Savings

After monitoring the blower under normal plant operation, the following results were achieved:

-

Energy savings rate: 40% compared with the Roots blower

-

Annual electricity cost savings: USD 14,800

-

Noise reduction: Significant improvement in working environment

-

Maintenance demand: Greatly reduced due to oil-free, contact-free design

The return on investment (ROI) was calculated at less than one year, making this project not only technically effective but also financially attractive.

Customer Feedback

The plant management was highly satisfied with the outcome. Their feedback was clear and direct:

“It’s quieter, more efficient, and the savings are real. We should have done this earlier.”

This statement reflects the broader reality for many wastewater treatment plants: while traditional blowers may appear reliable, they often cost much more in long-term energy and maintenance expenses.

Why RAETTS Air Suspension Blowers?

RAETTS has become a trusted choice for municipal and industrial wastewater plants due to its advanced air suspension and magnetic levitation blower technologies.

Key advantages include:

-

High Energy Efficiency – Saving 30–45% compared with Roots blowers.

-

Oil-Free & Maintenance-Free Design – No lubricants required, less downtime.

-

Low Noise & Vibration – Creating a safer and quieter working environment.

-

Smart Control System – Real-time monitoring, automatic adjustment to airflow demand.

-

Proven ROI – Short payback period, reducing overall operational costs.

Broader Impact on Wastewater Treatment Plants

For wastewater treatment facilities, upgrading to RAETTS air suspension or maglev blowers is more than just an equipment change:

-

It is a strategic investment in energy efficiency.

-

It helps plants meet stricter discharge standards through stable and reliable aeration.

-

It contributes to sustainable operations, reducing carbon footprint while lowering costs.

As governments and industries worldwide push toward green and low-carbon development, RAETTS blower technology is helping plants align with global sustainability goals.

Conclusion

The Zhejiang project demonstrates how a simple replacement — switching from a 37 kW Roots blower to a 22 kW RAETTS air suspension blower — can result in:

-

40% energy savings

-

USD 14,800 annual electricity savings

-

ROI in less than one year

For wastewater treatment plants under pressure to reduce costs and improve efficiency, RAETTS offers a proven solution. Our blowers are not just machines — they are investments in energy efficiency, reliability, and sustainability.

By choosing RAETTS, operators can ensure long-term cost savings, compliance with environmental standards, and a cleaner, greener future. 🌱

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424