Why More Pulp & Paper Wastewater Plants Are Specifying Maglev Turbo Blowers for Aeration

A Case Study of a 3 × 55kW Maglev Blower Installation in an Industrial WWTP

As energy costs rise and environmental regulations tighten, pulp and paper wastewater treatment plants are under increasing pressure to reduce operating costs while maintaining stable biological treatment performance. Aeration systems, often accounting for 40–60% of total WWTP energy consumption, have become the primary focus of plant upgrades.

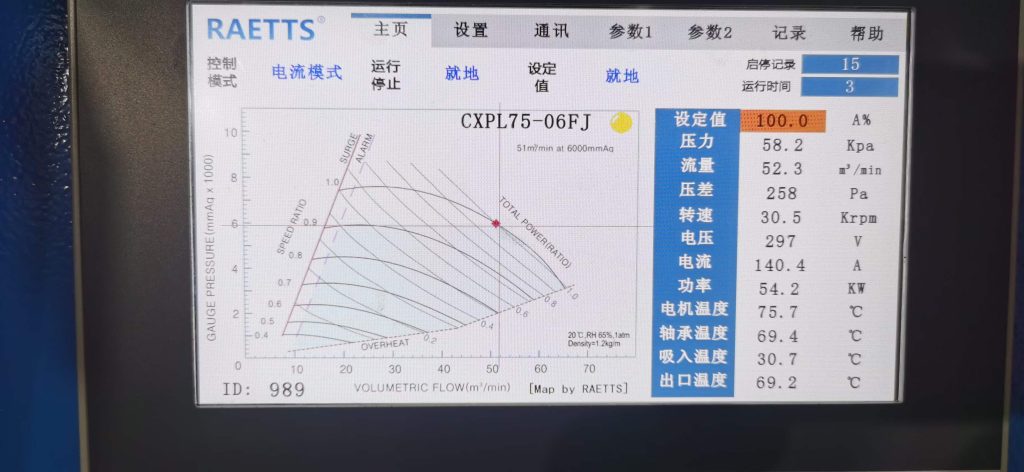

In a recent project, RAETTS successfully installed three 55kW maglev turbo blowers at a large pulp and paper mill wastewater treatment plant, delivering 51 m³/min at 60 kPa per unit. The project highlights why maglev blower technology is rapidly becoming the preferred choice for modern industrial wastewater treatment.

Project Overview: Aeration Upgrade for a Pulp & Paper WWTP

-

Application: Industrial wastewater treatment (pulp & paper)

-

Blower configuration: 3 × 55kW maglev turbo blowers

-

Operating point: 51 m³/min @ 60 kPa

-

Process: Biological aeration

Unlike traditional Roots blowers previously used in similar applications, the maglev turbo blowers were selected to address high energy consumption, frequent maintenance, noise issues, and unstable airflow control under variable load conditions typical of pulp and paper wastewater.

Why Maglev Blowers Outperform Traditional Roots Blowers in Industrial WWTPs

1. High-Efficiency PMSM for Lower Power Consumption

RAETTS maglev blowers are equipped with high-efficiency Permanent Magnet Synchronous Motors (PMSM), reaching efficiency levels of up to 96%. Compared with conventional three-phase asynchronous motors used in Roots blowers (typically around 88%), this results in significantly lower electrical losses, especially under partial-load operation.

For pulp and paper wastewater plants, where influent flow and organic load fluctuate, high motor efficiency across a wide operating range directly translates into measurable energy savings.

2. Three-Dimensional Aerodynamic Impeller for Maximum Air Efficiency

The blower features a three-dimensional, high-speed impeller, optimized using advanced aerodynamic design principles. With impeller efficiency reaching up to 87%, the system delivers more airflow per kilowatt compared to traditional positive displacement or two-dimensional impeller designs, which typically operate around 60% efficiency.

This makes maglev turbo blowers particularly suitable for high-load industrial aeration processes, where airflow demand is both high and variable.

3. Oil-Free Maglev Bearings: Zero Maintenance, Maximum Stability

At the core of maglev technology are active magnetic bearings, which fully suspend the rotor without mechanical contact. This design eliminates:

-

Lubricating oil systems

-

Mechanical wear

-

Bearing-related failures

For WWTP operators, this means near-zero routine maintenance, reduced downtime, and a much longer service life compared with traditional Roots blowers using ball bearings and gearboxes.

4. Ultra-Stable Operation Under Variable Load Conditions

Pulp and paper wastewater often experiences rapid changes in load and airflow demand. RAETTS maglev blowers use advanced control algorithms to maintain stable operation even during frequent load fluctuations, ensuring:

-

Consistent dissolved oxygen (DO) levels

-

Smooth startup and shutdown

-

Reliable long-term operation

This level of stability is increasingly important as plants move toward smart aeration and automated control strategies.

5. Low Noise and Improved Working Environment

Thanks to the absence of mechanical contact and high-precision balancing, maglev turbo blowers operate with significantly lower noise and vibration. This improves the working environment for operators and reduces the need for additional noise-control infrastructure.

A Clear Industry Trend: Maglev Blowers as the New Standard

Based on recent projects across industrial and municipal wastewater treatment plants, more owners and EPC contractors now specify maglev turbo blowers directly in tender documents, rather than listing them as optional alternatives.

The reasons are clear:

-

Lower life-cycle cost

-

Reduced maintenance workload

-

Higher energy efficiency

-

Better suitability for modern, automated WWTPs

Maglev turbo blowers are no longer considered “advanced alternatives” — they are becoming the default aeration technology for high-performance wastewater treatment facilities.

Conclusion: A Smarter Aeration Choice for Pulp & Paper Wastewater Treatment

The successful operation of 3 × 55kW RAETTS maglev turbo blowers in this pulp and paper wastewater treatment plant demonstrates how modern aeration technology can deliver higher efficiency, greater stability, and lower operating costs.

For WWTPs planning blower replacement or energy-saving upgrades, maglev turbo blowers offer a future-ready solution aligned with today’s sustainability and operational goals.

👉 Contact RAETTS for blower selection support, energy-saving calculations, and customized aeration solutions for industrial wastewater treatment.

E-mail: sales@raettsgroup.com

WhatsApp: +86 137 1270 2424