Maglev centrifugal chillers operate based on the vapor compression refrigeration cycle, enhanced by advanced magnetic bearing technology. This combination enables exceptionally high energy efficiency, oil-free operation, and reliable long-term performance. Below is a clear explanation of how a maglev centrifugal chiller works and why it represents the next generation of cooling technology.

Low-temperature, low-pressure refrigerant vapor from the evaporator is drawn into the centrifugal compressor. The compressor is driven by a permanent magnet synchronous motor (PMSM), while the rotor is fully supported by active magnetic bearings.

Thanks to magnetic levitation, the rotor operates in a non-contact, friction-free state, allowing it to rotate at very high speeds with exceptional stability.

In the first-stage impeller, the refrigerant vapor gains energy and its pressure increases to an intermediate level.

The refrigerant then mixes with flash gas from the economizer and enters the second-stage impeller, where it is further compressed.

After compression, the refrigerant exits the compressor at high pressure and high temperature and flows into the condenser.

The high-temperature, high-pressure refrigerant vapor enters the condenser, where it exchanges heat with cooler water flowing through copper tubes.

As heat is released, the refrigerant cools down and condenses into a liquid at saturation pressure.

The cooling water absorbs the heat and exits the condenser at a higher temperature, completing the heat rejection process.

The high-pressure liquid refrigerant leaving the condenser passes through an economizer, where it is subcooled to improve system efficiency.

It then flows through a throttling device, typically an electronic expansion valve (EEV), where:

Pressure and temperature drop rapidly

The refrigerant becomes a low-pressure, low-temperature liquid, ready to enter the evaporator

Inside the evaporator, the low-pressure refrigerant absorbs heat from the chilled water (or another secondary fluid).

As it absorbs heat, the refrigerant evaporates into vapor, cooling the chilled water in the process

The cooled water is then supplied to the building or industrial process for air conditioning or process cooling

The refrigerant vapor is once again drawn into the compressor, and the cycle repeats continuously to provide stable and efficient cooling.

Magnetic bearing technology is the core innovation that sets these chillers apart from conventional systems.

By using electromagnetic forces to precisely control the rotor position, the compressor operates with:

Zero mechanical contact

No friction and no wear

No lubricating oil or oil system

This results in:

Significantly reduced energy losses

Higher overall system efficiency

Longer equipment lifespan

Lower maintenance costs

Ultra-low noise and vibration levels

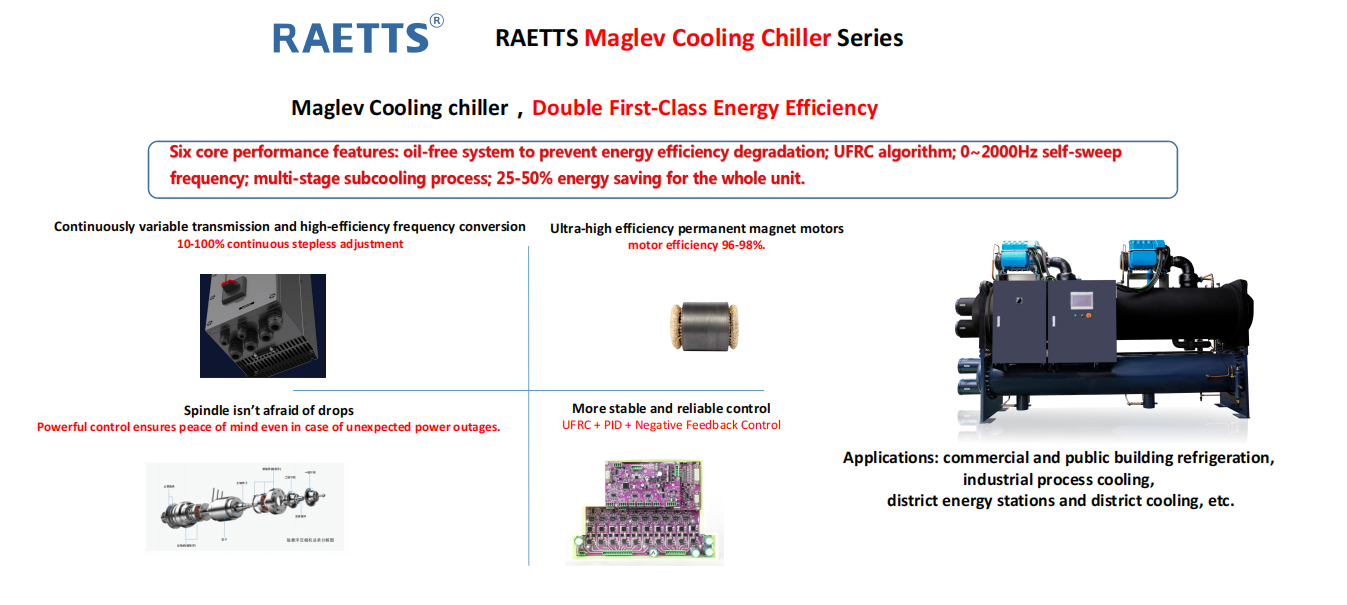

Maglev centrifugal chillers combine proven refrigeration principles with cutting-edge magnetic levitation technology to deliver oil-free, energy-efficient, and highly reliable cooling solutions. They are ideal for applications where efficiency, sustainability, and long-term operational savings are critical—such as commercial buildings, data centers, district cooling, and industrial processes.

As energy efficiency standards continue to rise worldwide, maglev centrifugal chillers are becoming a smart, future-ready choice for modern cooling systems.

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)