Why Is Regular Maintenance Crucial for Turbo Blower Performance?

Regular maintenance of turbo blowers is essential for ensuring their optimal performance and extending their lifespan. RAETTS, a leading turbo blower manufacturer, emphasizes that without proper maintenance, turbo blowers can suffer from reduced efficiency, increased energy consumption, and costly breakdowns. Routine checks help identify minor issues before they escalate into major problems, ensuring that the blower continues to operate at peak efficiency. This not only enhances performance but also improves cost performance by minimizing downtime and repair expenses.

For industrial applications, turbo blowers play a critical role in processes such as wastewater treatment, air handling, and industrial drying. By following a comprehensive maintenance schedule, companies can ensure consistent operation, reduced wear and tear, and a longer operational life for their equipment. RAETTS provides detailed guidelines and support for maintaining their blowers, making them a reliable partner for factories, agents, and distributors looking to enhance the efficiency and durability of their systems.

How Can You Perform Effective Maintenance on a Turbo Blower?

Effective maintenance of a turbo blower involves several key steps, starting with regular inspections of critical components such as the impeller, bearings, and filters. RAETTS recommends that operators inspect these parts for signs of wear, dirt accumulation, or damage, as these can negatively impact the blower’s performance. Cleaning or replacing air filters and ensuring that the impeller is free from debris will help maintain smooth airflow and prevent unnecessary strain on the motor.

Lubricating the bearings and other moving parts is another crucial maintenance task, as it reduces friction and prevents premature wear. RAETTS also advises monitoring the electrical components, such as checking for overheating or irregular voltage. Regular calibration of the blower’s control systems ensures that the blower operates efficiently, delivering optimal air pressure and flow. These preventive measures, when carried out consistently, can significantly improve the blower’s cost performance and reduce the need for major repairs or replacements.

For companies that require custom solutions, RAETTS offers OEM/ODM services, allowing clients to tailor their turbo blowers for specific operational requirements. With these customized designs, RAETTS ensures that the blower is engineered for long-term reliability, making maintenance easier and more effective.

Advantages of Maintaining RAETTS Turbo Blowers

Proper maintenance of RAETTS turbo blowers provides numerous advantages, including enhanced performance, energy efficiency, and prolonged equipment lifespan. Regular upkeep prevents operational disruptions, ensuring that factories, suppliers, and agents enjoy reliable performance with minimal downtime. By following RAETTS’ recommended maintenance guidelines, businesses can optimize their turbo blowers’ performance and achieve significant cost savings over time.

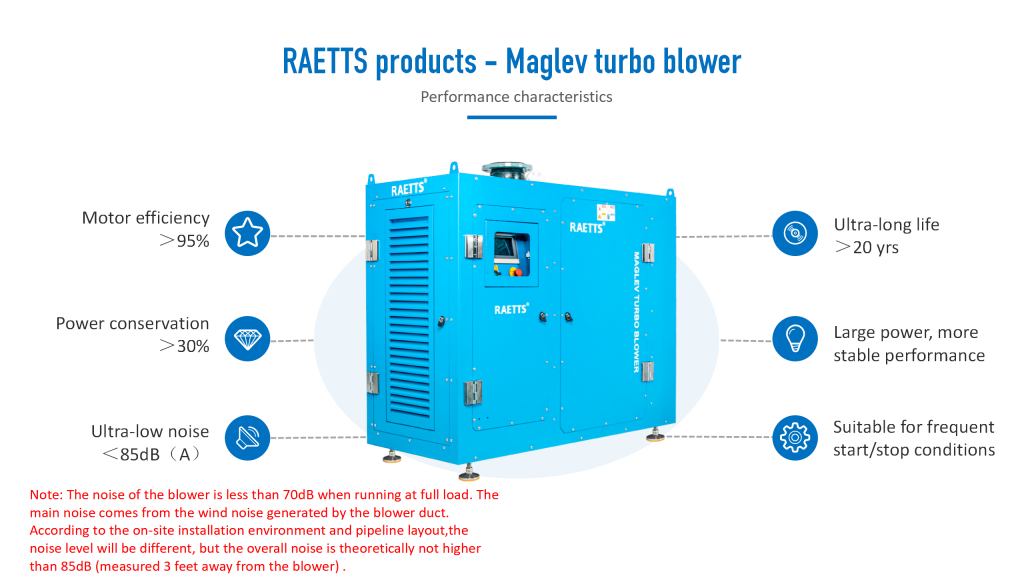

RAETTS’ focus on manufacturing high-quality turbo blowers, combined with their expertise in R&D and design, ensures that their products are designed for durability and ease of maintenance. Their blowers are built with advanced technology to meet the demanding needs of industrial environments, making them a valuable asset for operations that prioritize efficiency and cost performance.

Conclusion

Maintaining turbo blowers is essential for ensuring optimal performance, energy efficiency, and a long lifespan. RAETTS, as a trusted turbo blower manufacturer, offers comprehensive support and guidance for maintaining their blowers, helping businesses achieve superior cost performance. By following regular maintenance practices, industries can extend the life of their turbo blowers and ensure consistent, reliable operation, making RAETTS a reliable partner for businesses worldwide.