RAETTS, a leading turbo blower manufacturer, is renowned for producing high-performance air bearing blowers designed to optimize efficiency and durability in various industrial applications. Our air bearing blowers are engineered to deliver powerful airflow with minimal energy consumption, making them an essential component in industries requiring clean, oil-free, and reliable air. This article delves into the technical specifications of RAETTS air bearing blowers and highlights their key uses in various sectors, providing a comprehensive understanding of their capabilities and benefits.

What Are the Key Features of RAETTS Air Bearing Blowers?

Cutting-Edge Air Bearing Technology

RAETTS air bearing blowers utilize advanced air bearing technology, which allows the rotor to levitate and rotate without any physical contact with the bearings. This results in a frictionless, oil-free operation that significantly reduces wear and tear, prolonging the blower’s lifespan and ensuring consistent performance over time.

High-Speed Direct Drive

Our air bearing blowers are equipped with a high-speed direct drive motor, capable of reaching speeds up to 100,000 RPM. This high-speed rotation enables the blower to deliver powerful airflow while maintaining efficiency, making it suitable for applications where high pressure and large volumes of air are required.

Energy Efficiency and Eco-Friendliness

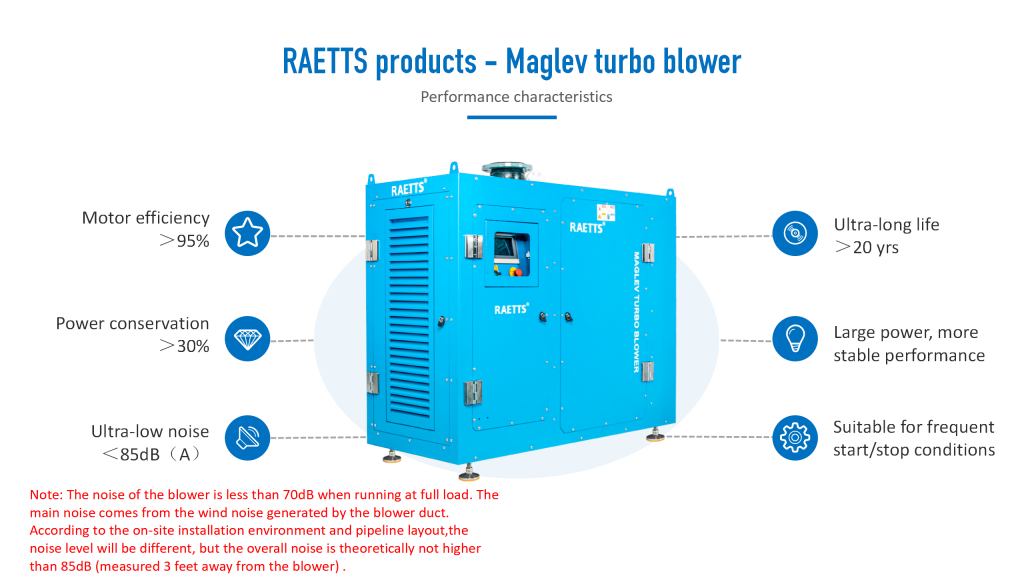

RAETTS air bearing blowers are designed to be highly energy-efficient. By reducing friction and eliminating the need for lubrication, the blowers consume less power compared to traditional models. This efficiency translates into lower operating costs and reduced environmental impact, making them an ideal choice for companies seeking sustainable solutions.

Oil-Free and Maintenance-Free Operation

One of the standout features of RAETTS air bearing blowers is their oil-free design. Without the need for lubrication, these blowers operate cleanly and require minimal maintenance. This makes them perfect for industries where contaminant-free air is critical, such as food processing, pharmaceuticals, and electronics.

Compact and Lightweight Design

Our air bearing blowers are compact and lightweight, making them easy to install and integrate into existing systems. Their small footprint ensures they can be used in facilities with limited space, while their lightweight nature allows for easier handling and transport.

What Are the Technical Specifications of RAETTS Air Bearing Blowers?

Performance Parameters

RAETTS air bearing blowers are available in various models to suit different industrial needs. Here are the general technical specifications for our standard units:

- Air Flow Rate: 50 to 1200 cubic meters per hour (m³/h), depending on the model

- Operating Pressure: Up to 0.8 bar, ideal for high-pressure applications

- Motor Power: Ranges from 7.5 kW to 75 kW, ensuring optimal performance for diverse industrial requirements

- Rotation Speed: Up to 100,000 RPM, providing powerful airflow and efficient operation

- Noise Level: Less than 75 dB, ensuring quiet operation in sensitive environments

- Energy Efficiency: Achieves energy savings of up to 30% compared to traditional blowers

- Weight: 50 to 500 kg, depending on the model

Materials and Construction

- Rotor Material: High-strength titanium or aluminum alloy, designed for durability and lightweight performance

- Casing Material: Stainless steel or aluminum, offering corrosion resistance and structural strength

- Bearings: Air bearings that eliminate the need for oil or lubrication, contributing to the maintenance-free design

Uses and Applications of RAETTS Air Bearing Blowers

RAETTS air bearing blowers are highly versatile and suitable for a range of industrial applications. Their high efficiency, oil-free operation, and compact design make them valuable assets in numerous industries.

Wastewater Treatment

RAETTS air bearing blowers are widely used in wastewater treatment plants for aeration purposes. Their ability to deliver large volumes of air efficiently is critical in ensuring proper oxygenation of wastewater, which is essential for the biological treatment process. The energy-efficient design helps plants reduce operational costs while maintaining environmental compliance.

Textile and Paper Industry

In the textile and paper industry, air bearing blowers are used for drying applications. Their oil-free design ensures that no contaminants are introduced into the drying process, ensuring the quality of the final product. Additionally, the high-speed airflow allows for faster drying times, improving production efficiency.

Air Knife Drying and Cleaning

RAETTS air bearing blowers are ideal for air knife systems, which are used in various industries for drying, cleaning, or cooling processes. The high-pressure airflow generated by the blowers allows for effective removal of moisture, dust, or debris from products, making them essential in food processing, packaging, and automotive industries.

Electronics Manufacturing

In the electronics industry, contamination-free environments are crucial for the production of sensitive components. RAETTS air bearing blowers provide clean, oil-free air for cooling and cleaning applications, ensuring that electronic products remain free of contaminants during manufacturing.

Food and Beverage Industry

RAETTS air bearing blowers are also used in the food and beverage industry, where clean air is necessary for drying and cooling food products. The oil-free design ensures that the air remains uncontaminated, maintaining product quality and safety standards. Additionally, the blowers’ energy efficiency helps food processing plants reduce their carbon footprint.

How Do RAETTS Air Bearing Blowers Benefit Your Business?

Reduced Operational Costs

Thanks to their energy-efficient design, RAETTS air bearing blowers can reduce power consumption by up to 30% compared to traditional blowers. This energy efficiency translates into significant cost savings over time, making them a wise investment for any business.

Minimal Maintenance Requirements

The oil-free, frictionless operation of RAETTS air bearing blowers means fewer parts are subject to wear and tear. As a result, these blowers require minimal maintenance, reducing downtime and associated maintenance costs.

Enhanced Durability and Longevity

With no mechanical contact between moving parts, RAETTS air bearing blowers experience less wear, resulting in a longer lifespan. The high-quality materials used in their construction ensure that they can withstand harsh industrial environments while maintaining optimal performance.

Conclusion: RAETTS Air Bearing Blowers for Efficient and Sustainable Industrial Applications

RAETTS air bearing blowers offer a powerful, energy-efficient, and maintenance-free solution for a wide range of industrial applications. Whether you’re looking to improve efficiency in wastewater treatment, enhance product quality in the food and electronics industries, or optimize drying and cleaning processes, RAETTS has a blower model to meet your needs.

With a focus on high performance, durability, and sustainability, RAETTS air bearing blowers are an investment in the long-term success of your operations. Let RAETTS be your trusted partner in delivering cutting-edge turbo blower technology for your business.