In the dynamic environment of a theatre, maintaining a clean and safe space for both performances and equipment is essential. Whether it’s the complex lighting systems, intricate sound equipment, or mechanical stage setups, keeping all these elements in top condition is crucial to avoid unexpected failures and ensure high-quality performances. Regular maintenance of theatre equipment, especially in high-use environments, requires careful attention to cleanliness, cooling, and moisture control.

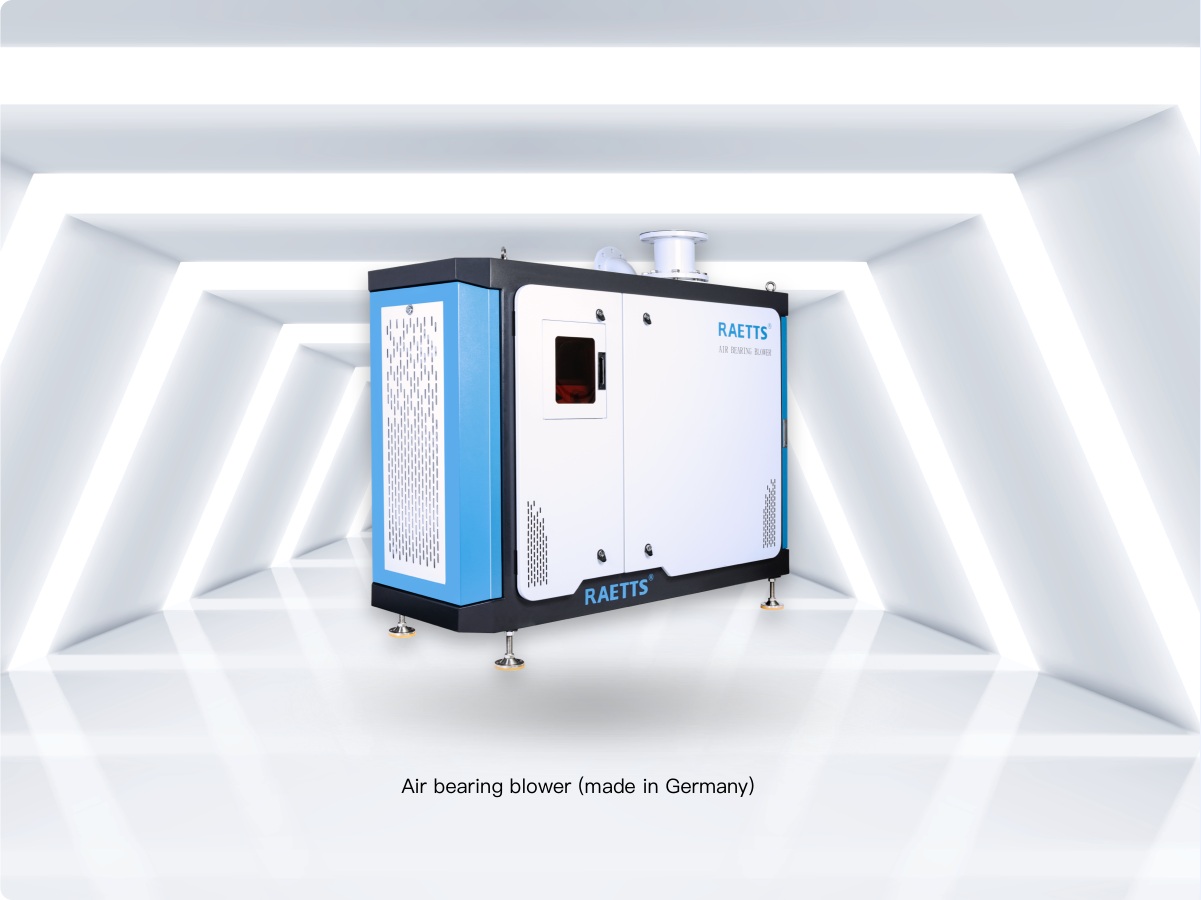

One of the most effective tools for maintaining theatre equipment is the air blower machine. RAETTS, a leading turbo blower manufacturer, specializes in creating high-performance air blowers that help keep theatre equipment in optimal working condition. By improving air circulation, reducing moisture buildup, and facilitating faster cleaning, RAETTS turbo blowers ensure the longevity and reliability of essential theatre systems.

In this article, we’ll explore how RAETTS air blower machines can be used for theatre equipment maintenance, detailing the best practices for using turbo blowers in this unique environment.

The Importance of Regular Theatre Equipment Maintenance

Theatre equipment, such as lighting systems, sound equipment, stage machinery, and special effects devices, is used heavily during performances, often under stressful and high-heat conditions. The consequences of neglecting maintenance can be costly, leading to equipment failures, system malfunctions, or safety hazards. Regular maintenance helps:

- Ensure equipment longevity: Proper care can extend the life of expensive theatre equipment.

- Prevent unexpected breakdowns: Routine checks and maintenance can help detect potential issues before they lead to costly failures.

- Maintain safety standards: Ensuring all equipment is properly maintained reduces the risk of accidents caused by malfunctioning devices.

- Improve performance quality: Well-maintained equipment delivers more reliable, consistent, and high-quality results during shows.

One of the simplest yet most effective ways to maintain theatre equipment is by using RAETTS turbo blowers to manage airflow, clean sensitive components, and maintain optimal operating conditions.

How RAETTS Air Blower Machines Improve Theatre Equipment Maintenance

Air blower machines from RAETTS are powerful, efficient, and versatile tools designed to assist with the maintenance of theatre equipment. Whether you’re cleaning intricate machinery, managing heat buildup, or preventing moisture damage, RAETTS turbo blowers can be a game-changer in your equipment care strategy. Here are several ways these blowers contribute to better theatre equipment maintenance:

1. Effective Cooling and Heat Dissipation

Many theatre systems, especially lighting and sound equipment, generate a significant amount of heat during performances. Excessive heat can lead to system failures, overheating of sensitive components, or even fires in extreme cases. RAETTS turbo blowers are designed to provide high-volume airflow, which is ideal for cooling and dissipating heat from equipment like stage lights, sound systems, and special effects machinery.

By maintaining a consistent, controlled airflow, RAETTS air blowers help to regulate the temperature of critical theatre equipment, preventing overheating and extending the lifespan of sensitive electronics.

Best Practices for Heat Management with RAETTS Air Blowers:

- Position RAETTS turbo blowers to direct airflow toward lighting rigs and audio equipment, which are often placed in tight, enclosed spaces that tend to trap heat.

- Use blowers to cool down equipment after use, particularly in environments where lighting and sound systems are used continuously over long periods.

- Maintain optimal airflow circulation within server racks or equipment rooms to prevent heat buildup and ensure proper ventilation.

RAETTS Tip: Ensure air blowers are directed at the ventilation openings of equipment like amplifiers and projectors to prevent heat from accumulating.

2. Cleaning and Dust Removal from Equipment

Dust and debris can build up on equipment over time, affecting both functionality and aesthetics. This is particularly important for theatre lighting and sound equipment, where dust can obstruct vents, degrade performance, and potentially cause electrical problems. RAETTS turbo blowers offer an efficient solution for removing dust and debris from sensitive equipment without the need for contact-based cleaning, which can be time-consuming and potentially damaging.

RAETTS air blowers provide high-pressure airflow to dislodge dust from hard-to-reach areas, cooling fans, vents, and electrical components, helping to maintain optimal performance and reduce the risk of overheating.

Best Practices for Dust Removal:

- Regularly blow out dust from lighting rigs, audio systems, speakers, and projectors to ensure clean airflow and avoid overheating.

- Use RAETTS turbo blowers to clean the intake vents and exhaust fans of air conditioning systems, which are critical for maintaining the climate in the theatre.

- Clean hard-to-reach areas such as stage machinery, soundboard equipment, and control panels to prevent the buildup of dust that could affect performance.

RAETTS Tip: Utilize RAETTS air blowers as part of your regular maintenance routine to ensure that dust doesn’t accumulate and negatively impact the performance of your equipment.

3. Moisture Control to Prevent Corrosion

Moisture can be a serious concern for theatre equipment, especially in environments where humidity levels are high, or there are sudden temperature fluctuations. RAETTS turbo blowers are particularly effective at reducing moisture buildup on electrical components, reducing the risk of corrosion and short-circuits.

Excess moisture can seep into sensitive electronics, causing malfunction or corrosion over time. By directing RAETTS turbo blowers at critical equipment such as control panels, soundboards, and lighting fixtures, you can ensure that moisture is quickly dissipated, preventing damage.

Best Practices for Moisture Control with RAETTS Air Blowers:

- Use RAETTS turbo blowers after cleaning or during humidity spikes to quickly dry out electronics, connectors, and switches.

- Position the blowers in areas prone to moisture, such as backstage equipment rooms, power distribution panels, and lighting rigs, to reduce moisture buildup.

- Blow out equipment after rain or high humidity events, especially if the theatre has an outdoor stage or is in a humid climate.

RAETTS Tip: For better moisture control, use RAETTS turbo blowers in conjunction with dehumidifiers to maintain optimal conditions in equipment rooms and on the stage.

4. Preventing Static Build-Up and ESD Damage

Electrostatic discharge (ESD) is a constant risk in environments with sensitive electronic equipment like sound systems, lighting controls, and projection devices. RAETTS turbo blowers help mitigate static build-up by providing airflow that reduces the likelihood of static charge accumulation. By directing air over surfaces that are prone to ESD, you can keep equipment functioning properly and prevent costly damage to delicate components.

Best Practices for ESD Prevention:

- Use RAETTS turbo blowers to direct air toward stage lighting, sound equipment, and other sensitive electronics to prevent static discharge.

- Ensure that blowers are placed near control boards, servers, or switch panels to help dissipate static charges that could damage components.

- Maintain clean air around sensitive equipment using RAETTS turbo blowers to reduce particle and moisture buildup that can contribute to static build-up.

RAETTS Tip: Integrating RAETTS turbo blowers with static-dissipative mats and antistatic sprays helps create a safer, more stable environment for electronic equipment.

5. Reducing Downtime and Increasing Efficiency

The more efficiently your equipment is maintained, the less downtime you will experience, allowing for smoother performances and fewer interruptions. RAETTS turbo blowers offer a fast and effective way to clean, cool, and maintain theatre systems, which ultimately increases operational efficiency and reduces the time required for upkeep.

Best Practices for Operational Efficiency:

- Use RAETTS air blowers to speed up routine cleaning tasks, such as dusting, moisture removal, and cooling, allowing your team to focus on more important tasks.

- Regularly use blowers to maintain air circulation in equipment rooms, ensuring that cooling systems run efficiently and prevent downtime due to overheating.

- Schedule regular maintenance of your lighting and sound equipment with RAETTS turbo blowers to keep them functioning smoothly without the need for disruptive repairs.

RAETTS Tip: Incorporate RAETTS turbo blowers into your maintenance schedule to ensure that your equipment is always ready for performance, minimizing downtime and maximizing reliability.

Conclusion: Enhance Theatre Equipment Maintenance with RAETTS Turbo Blowers

Theatre equipment maintenance requires an integrated approach that includes cleaning, cooling, moisture control, and static discharge prevention. RAETTS turbo blowers provide an efficient, cost-effective solution for maintaining the equipment essential for high-quality theatre performances.

By using RAETTS air blower machines, theatre technicians can ensure that:

- Equipment stays cool and performs optimally, reducing the risk of overheating and system failures.

- Dust and debris are removed quickly and efficiently, preventing equipment malfunctions.

- Moisture is controlled, reducing the risk of corrosion or short-circuiting.

- Static build-up is minimized, protecting sensitive electronics from ESD damage.

Incorporating RAETTS turbo blowers into your theatre maintenance routine will lead to enhanced equipment reliability, better performance quality, and reduced operational downtime. Contact RAETTS today to learn more about our high-performance air blowers and how they can support your theatre’s equipment maintenance needs.