What is air bearing blower?

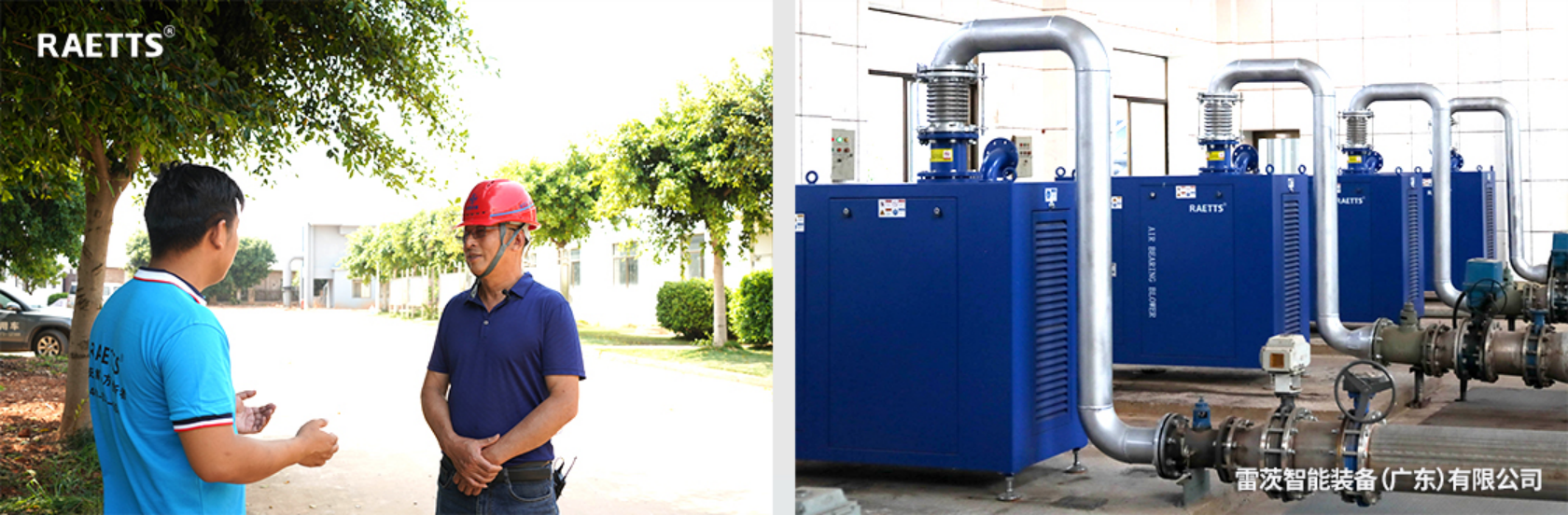

RAETTS is proud to introduce our revolutionary product – the air bearing blower, specifically designed for high precision and efficient air movement.

The air bearing blower is the perfect choice for industries that require high accuracy and smooth air flow, such as semiconductor manufacturing, medical equipment production, and aerospace engineering. The absence of mechanical contact in our blower eliminates friction and vibration, resulting in a whisper-quiet operation and a longer lifespan. This has made it a popular choice for automation systems, where precision and reliability are essential. One of the key features of our air bearing blower is its energy efficiency. By using air as a lubricant and eliminating the need for oil or grease, our blower is environmentally friendly and consumes less energy.

Type of air bearing blower

1. High-speed blower

This type of air bearing blower operates at a high rotational speed to provide a high flow rate of air or gas for applications such as pneumatic conveying, vacuum systems, and cooling processes.

2. Turbo blower

Also known as a turbofan blower, this type of blower uses a combination of a radial and axial impeller design to achieve high pressure and flow rates. It is commonly used in HVAC systems, power plants, and industrial processes.

3. Centrifugal blower

Similar to a turbo blower, a centrifugal blower uses centrifugal force to create airflow and is often used for ventilation, exhaust, and dust collection systems.

4. Turbo compressor

A turbo compressor is a type of blower that also compresses air or gas in addition to providing airflow. It is commonly used in gas turbines, refrigeration systems, and compressed air systems.

5. Efficient blower

These types of blowers utilize advanced design and technology to achieve high levels of efficiency in terms of energy consumption and air flow.

6. Low-noise blower

As the name suggests, low-noise blowers are designed to operate quietly, making them suitable for noise-sensitive environments such as hospitals, schools, and offices.

7. High-performance blower

These are high-end blowers designed for applications that require heavy-duty and continuous operation, such as in industrial processes and large-scale ventilation systems.

8. Oil-free blower

Oil-free blowers use alternative lubrication methods or advanced design techniques to eliminate the need for oil, making them ideal for applications where oil contamination is a concern, such as in food processing and medical equipment.

9. Energy-saving blower

Energy-saving blowers use advanced control systems and efficient designs to reduce energy consumption and operating costs, while still providing sufficient airflow for industrial processes.

10. Industrial blower

Industrial blowers are a broad category that encompasses all types of blowers used in industrial settings, including applications such as material handling, combustion, and drying processes.

What is maglev turbo blower?

Our latest innovation, the maglev turbo blower, combines the advantages of air bearing technology and the power of magnetic levitation, resulting in a state-of-the-art blower that is unprecedented in the market. Furthermore, the maglev turbo blower utilizes magnetic bearings, which greatly reduces friction and enhances efficiency. This cutting-edge technology not only saves energy but also reduces maintenance costs, making it a cost-effective solution for businesses.

Type of maglev turbo blower

1. Magnetic Levitation Maglev Turbo Blower

This type of blower uses magnetic levitation technology to support the rotor in a levitated position, eliminating the need for traditional bearings. This reduces friction and allows for high speed rotation and increased energy efficiency.

2. Electromagnetic Suspension Maglev Turbo Blower

Similar to magnetic levitation, this type of blower uses electromagnetic fields to achieve a levitated rotor position. This technology also allows for smooth operation and minimal maintenance.

3. Magnetic Bearing Maglev Turbo Blower

This type of blower utilizes permanent magnets to suspend the rotor and provide stable operation. It can handle high radial and axial loads, making it suitable for heavy duty applications.

4. Permanent Magnet Motor Maglev Turbo Blower

In this type of blower, the motor and impeller are directly connected without the need for a separate drive mechanism. This results in a compact and efficient design, with high power density and low maintenance.

5. Levitation Force Maglev Turbo Blower

The levitation force generated by the magnetic bearings in these blowers supports the rotor in a levitated position, reducing mechanical wear and increasing the lifespan of the blower.

6. Levitation Gap Maglev Turbo Blower

This refers to the distance between the rotor and the stator in a magnetic levitation blower. A smaller levitation gap allows for higher precision and stability in operation.

7. High-speed Rotation Maglev Turbo Blower

Using magnetic levitation or other advanced bearing technology, these blowers can achieve high rotational speeds for increased efficiency and performance.

8. Air Foil Bearing Maglev Turbo Blower

Instead of using traditional ball or roller bearings, this type of blower utilizes air foil bearings which provide low friction operation and can handle high-speed rotation.

9. Radial Load Maglev Turbo Blower

This refers to the force applied perpendicular to the shaft of a blower. Magnetic levitation and advanced bearing technologies allow for these blowers to handle high radial loads, making them suitable for heavy duty industrial applications.

10. Axial Load Maglev Turbo Blower

This refers to the force exerted along the axis of the blower shaft. Maglev turbo blowers are designed to handle high axial loads, making them suitable for applications with varying air flow and pressure requirements.

What is the difference between air bearing blower and maglev turbo blower?

RAETTS is a leading manufacturer of innovative and high-quality air and gas blower solutions. Our company prides itself on employing cutting-edge technology, extensive research and development, and efficient design to produce top-of-the-line products for our customers. As a recognized expert in the industry, we are constantly striving to meet and exceed our customers’ needs and expectations. In this article, we will introduce the key differences between our air bearing blower and maglev turbo blower.

Manufacturing and OEM/ODM:

RAETTS is dedicated to providing customized solutions to meet our customers’ specific requirements. Both our air bearing blower and maglev turbo blower are manufactured with precision and attention to detail using high-quality materials. Our company offers OEM/ODM services, allowing us to tailor our products to suit different needs and applications.

R&D and Design:

We have a team of experienced engineers who are constantly researching and developing new technologies and designs to improve the performance and efficiency of our blowers. Our air bearing and maglev turbo blowers are the result of years of research and development, ensuring that they are at the forefront of technological advancements.

Part I: Energy-saving

One of the key differences between our air bearing blower and maglev turbo blower is their energy efficiency. The air bearing blower utilizes aerodynamic bearings, which greatly reduces friction and energy loss, resulting in significant energy savings. On the other hand, the maglev turbo blower uses a state-of-the-art permanent magnet motor, which is known for its high efficiency and low power consumption.

Part II: Low-noise

Both our air bearing blower and maglev turbo blower are designed to operate with minimal noise. The aerodynamic bearings in the air bearing blower reduce friction and vibration, resulting in a significantly quieter operation. The permanent magnet motor in the maglev turbo blower is also known for its low noise levels, making it suitable for noise-sensitive environments.

Part III: Cost Performance

RAETTS aims to provide cost-effective solutions for our customers. Our air bearing blower and maglev turbo blower offer excellent cost performance, as they are designed to operate at high efficiency and low power consumption, resulting in reduced energy costs in the long run.

Rotating Assembly:

The rotating assembly in both our air bearing blower and maglev turbo blower is designed to maximize efficiency and stability. The air bearing blower uses a high-precision spindle, which minimizes vibration and ensures smooth operation. The maglev turbo blower’s permanent magnet motor also guarantees a stable and efficient performance, contributing to its overall durability.

Power Consumption:

Part V: Power consumption

In addition to their energy-saving capabilities, our air bearing blower and maglev turbo blower are also designed to operate at low power consumption. This not only helps to reduce energy costs, but also allows for a more reliable and consistent performance.

Durability:

Part VI: Durability

RAETTS products are built to last. The air bearing and maglev turbo blowers are constructed with high-quality materials and undergo rigorous testing to ensure their durability and long lifespan. Both blowers are also designed to operate at low temperatures, further prolonging their lifespan.

Convenience:

Part VII: Convenience of maintenance

Both our air bearing blower and maglev turbo blower require minimal maintenance, thanks to their high-quality materials and efficient design. Operation and maintenance are made easier with easily accessible parts and simple disassembly processes.

Target Audience/Market:

The key differences between our air bearing blower and maglev turbo blower make them suitable for a wide range of applications and industries. These include wastewater treatment, pneumatic conveying, food and beverage processing, and more. Whether our customers are looking for an energy-efficient solution, low-noise operation, or cost-effective performance, RAETTS has a blower to meet their specific needs.

In conclusion, RAETTS is committed to providing high-quality and innovative blowers to our customers. Our air bearing blower and maglev turbo blower offer distinct advantages and are designed to meet different industry needs. With our focus on energy efficiency, low noise levels, cost-effectiveness, and durability, we are confident that our blowers will exceed your expectations. Contact us today to learn more about our products and how they can benefit your operations.