RAETTS Products

Experts for air suspension and magnetic levitaion technologies.

RAETTS maglev centrifugal chiller(more than 40% energy saving than traditional chiller)

The RAETTS maglev centrifugal chiller unit oil-free variable frequency mainly solves the problems of traditional centrifuges, screw machines, and piston machines that have a large impact on the power grid, low temperature control accuracy, high operating costs, high maintenance costs, high noise, and high failure rate during the compressor startup process.

The maglev centrifugal chiller unit has many advantages such as ultra-high energy efficiency, oil-free lubrication, low land occupation, and low power distribution, and is a typical representative of the new generation of chiller hosts.

01

It adopts a falling film structure, which is more convenient for cleaning, less water resistance, and higher efficiency compared to plate heat ex-changer or dry evaporators.

02

Excellent partial load efficiency: compared to traditional compressors, the integrated partial load value (IPLV) of magnetic suspension compressors can be improved by more than 50%, which is very beneficial for situations where most of the time is under partial load. The COP of maglev centrifugal chiller unit used in this project is 9.82, which improves the efficiency by about 40% compared to the traditional screw full liquid unit, which means that the annual operating cost is saved by 40% compared to the screw unit.

03

Ultra low starting current: The starting current is 2A, greatly reducing the impact on the power grid. The power factor of the motor has reached 0.95, which has certain economic significance for the distribution system.

04

Super quiet operating noise: The full-load operating noise of the maglev centrifugal chiller full liquid unit is only below 65dB, which is more than 15dB lower than that of conventional units with the same cooling capacity.

05

Ultra low starting current: The starting current is 2A, greatly reducing the impact on the power grid. The power factor of the motor has reached 0.95, which has certain economic significance for the distribution system.

06

The maglev centrifugal chiller is used magnetic bearing. No lubricating oil needed, the bearings have no friction, reducing friction losses, saving the cost of the oil supply system, greatly reducing the cooling attenuation caused by lubricating oil, and is environmental friendly. The non lubricating oil system greatly reduces the maintenance work of the maglev centrifugal chiller unit, not only saving maintenance labor, but also greatly reducing maintenance costs. Compared to screw units with the same cooling capacity, the maintenance cost of the maglev centrifugal chiller unit is only 25%.

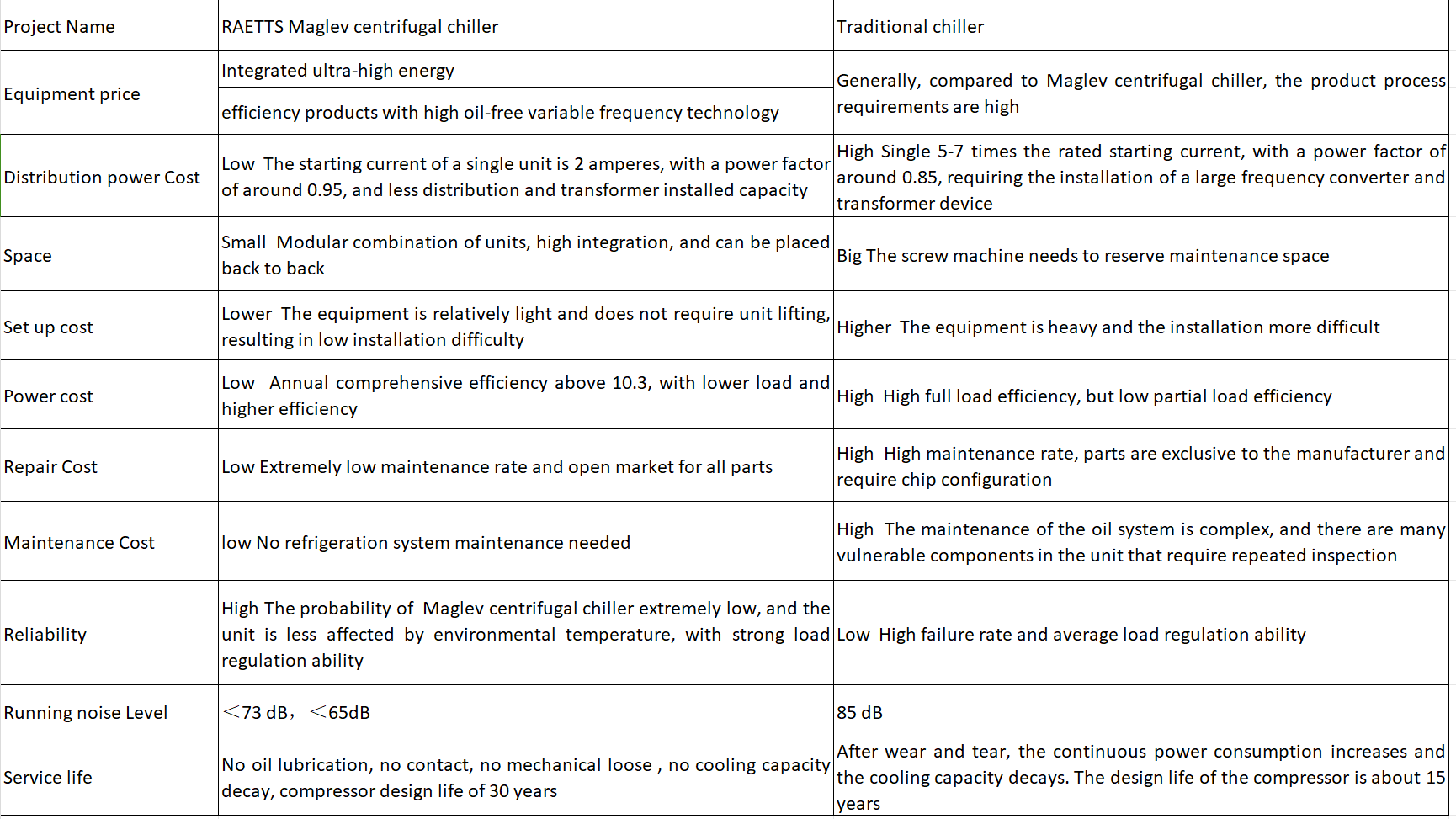

RAETTS chiller advantages

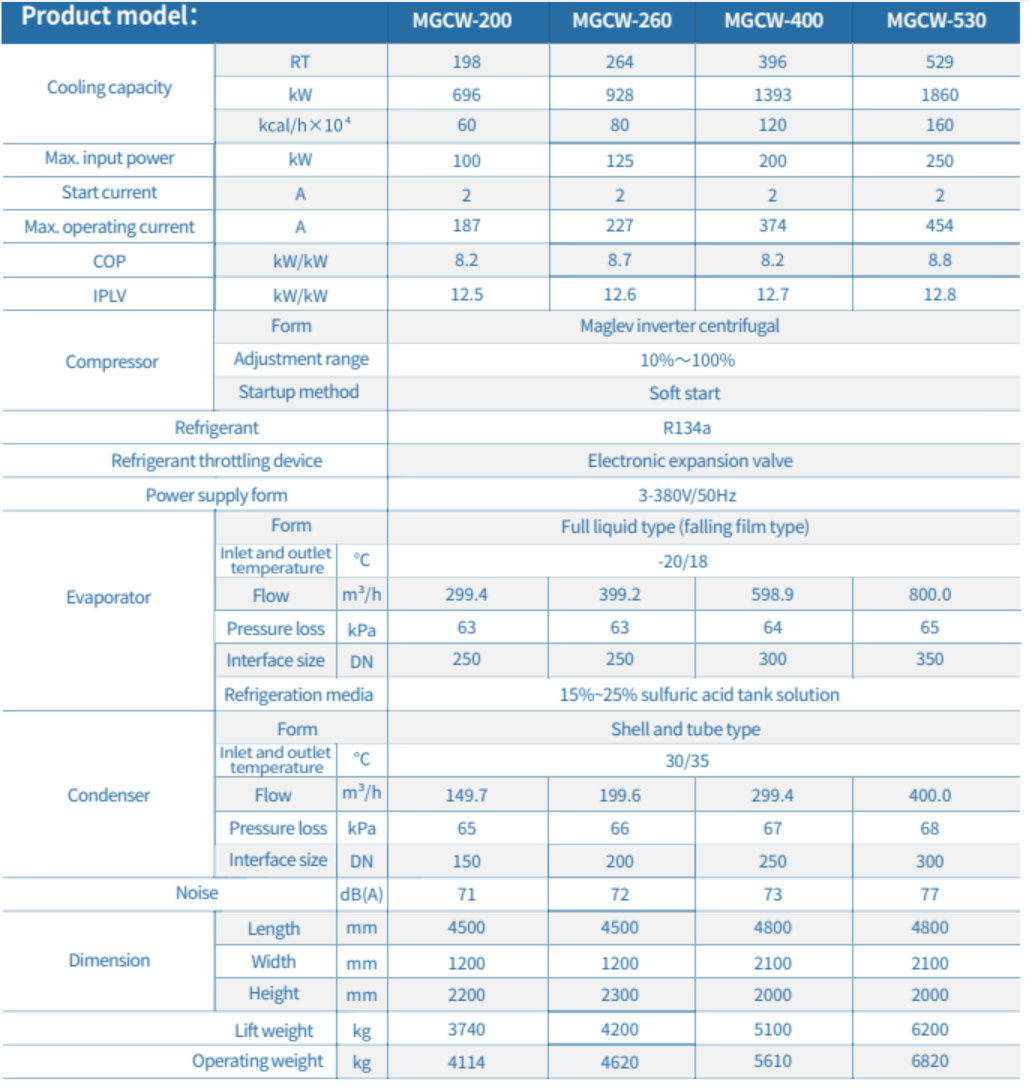

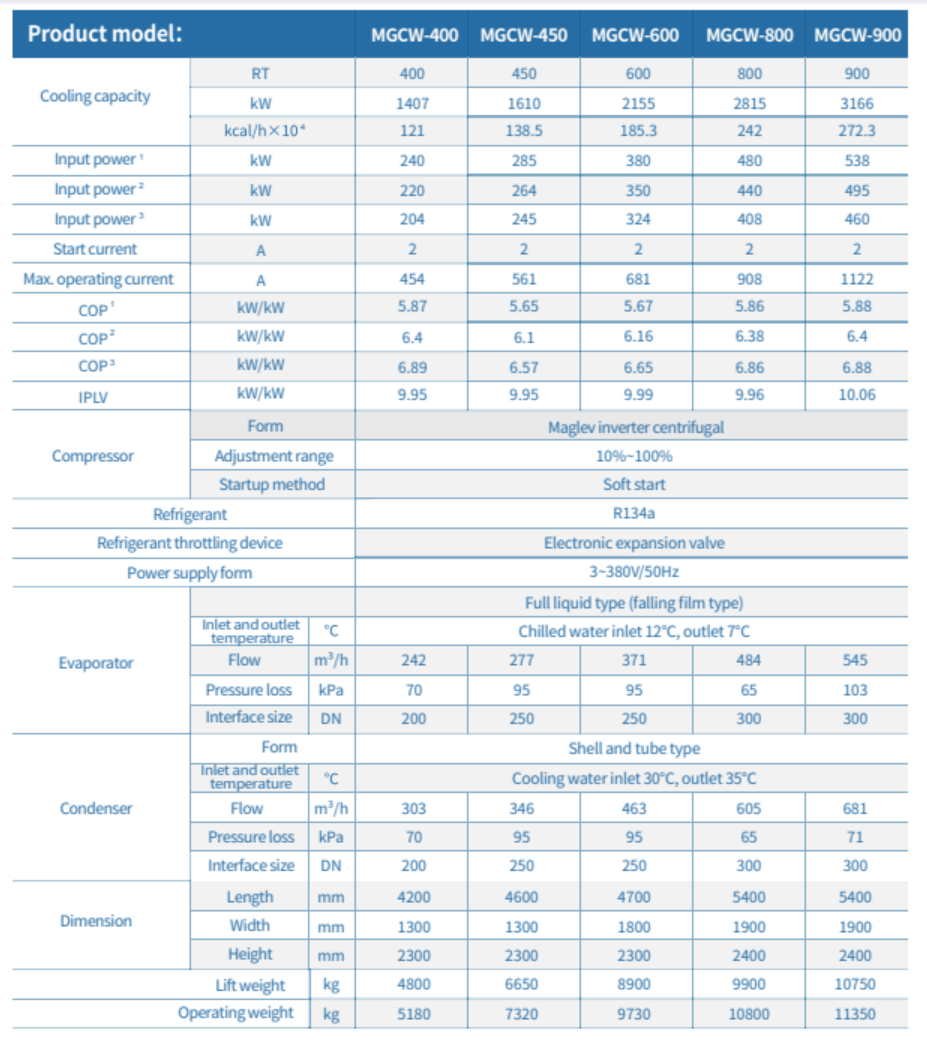

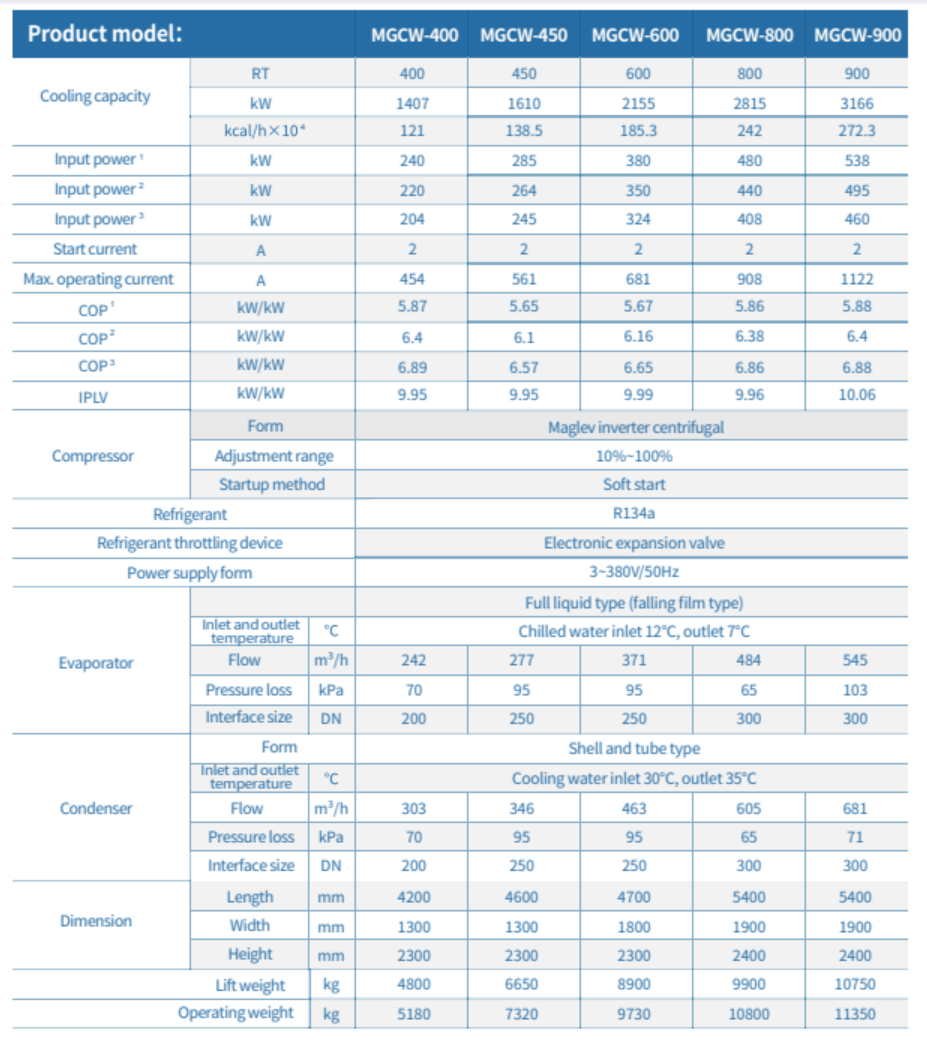

TECHNICAL PARAMETERS OF RAETTS MAGLEV CENTRIFUGAL CHILLER

RAETTS provides high efficiency and energy-saving system solutions for our global customers,contributing to achieve the goal of carbon peaking and carbon neutrality.

For more information, feel free to click here to submit your request,our professional team will contact you soon

RAETTS High-Tech Park No.3,Juyuan Second Road.Dongguan City,Guangdong Province, China

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)

BelPragma LLC

Address: Republic of Belarus, Minsk, st. Amuratorskaya, 4, office 214

RAETTS RUS LLC

Address: Moscow, Elektrozavodskaya st., 24/1

Phone: +7 (495) 767-35-35

Mail: sales@raetts.ru

ENCOTEC Co.,Ltd. Add: 71/296 Soi.Ramkhamhaeng 164,Ramkhamhaeng Rd.,Minburi,Bangkok 10510,Thailand

T&T Pacific Sdn Bhd Add:No.31, Jalan PJU 3/49,Sunway Damansara,47810 Petaling Jaya,Selangor Darul Ehsan

Add:21 Center Drive, Hillsdale, NJ 07642

ASAP Servicios Técnicos Add:Calle Zinc 1, Nave A,28770 Colmenar Viejo, Madrid (Spain)

Adresse : 80 Rue Isabelle Eberhardt, 34000 Montpellier.

Telephone: 0033(0)652678173

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)